Issue: New

Sort: Guard Defend, cylinder spherical rod

Material: Protective Cloth

Applicable Industries: Developing Material Stores, Production Plant, Machinery Repair Shops, Foods & Beverage Manufacturing facility, Construction works , Energy & Mining, cnc machine device

Showroom Spot: Canada, Philippines, Mexico, Russia, Thailand, Chile, Colombia

Movie outgoing-inspection: Presented

Equipment Check Report: Presented

Advertising and marketing Type: Regular Merchandise

Model: Ruiao

Design: Custom-made

Guarantee: More than 5 many years

Core Factors: Content nylon fabric

Excess weight (KG): .five

Identify: spherical shaft dust bellows protect

Function: oilproof , waterproof , dustproof

Coloration: black/ gray

Certification: ISO9001 CE

Traits: Higher temperature resistant

Software: safety hydraulic rod shaft

Packaging Particulars: wooden situations or carton or pallet

RUIAO company provide hydraulic cylinder protecting covers spherical bellows shaft rod dust includeRequirementsTitle: cnc device spherical cylinder shaft rod dust include

one. Content: rubber , nylon cloth and Artifical leather-based

2.CZPT PVC CZPT 3.If enduser pick information talked about fill in type , make sure you fill in a kind per kind , We acknowledge orders in accordance to user’s need

four. Characteristic: dustproof, oilproof, water-resistant, Received linear information rail is specialized in changing CZPT CZPT PMI H45F H45FL and H55F H55FL higher temperature resistance.

The spherical threaded rod bellows protect can avert the screw, shaft and bar from dust contamination and can transfer along with the device tool’s factors this kind of as strenching or contraction. Yet another sort according bellows include can stop the slideway from getting polluted by dust and scrap, bearing temperature from -20°~500°.Also, stainless metal material is also available, welcome e-mail us for far more particulars~

Comprehensive Pictures cnc device round shaft bellows adaptable hydraulic cylinder sewn bellow protect with zipper Our Company ZheJiang Ruiao Device Resource Components creating CO.,LTD. We are skilled making equipment device components,and have above twenty five many years experience to producing. our products have been bought several international locations, like Usa GERMANY CANADA Malaysia and so on. Our principal scorching sale products are engineering plastic cable drag chains, metal drag chains, chip conveyor sequence, equipment bellows include, oil mist collector, machine lamps and gentle tube&pipe, watertight connectors, anti vibration mounts and so on.You can check out our website,If you are intrigued, pls get in touch with me, I will give you great cost.

Certifications Packing & TMZ200 TMZ225 TMZ250 TMZ290 TMZ300 tadano truck crane slewing ring bearing Delivery Our most specialist packaging Transport of huge trucks to the seaport And worldwide transport cooperation Our Provider one. OEM Producing welcome: Solution, Package… 2. Sample get 3. We will reply you for your inquiry in 24 hrs.4. after sending, we will monitor the merchandise for you once every 2 times, right up until you get the goods. When you acquired the goods, examination them, and give me a suggestions.If you have any questions about the problem, speak to with us, we will supply the solve way for you.

FAQ Q1. What is your conditions of packing?A: Normally, we pack our items in neutral white bins and brown cartons. If you have legally registered patent, we can pack the items in your branded bins soon after acquiring your authorization letters. Q2. What is your phrases of payment?A: T/T 30% as deposit, and 70% just before shipping. We’ll display you the photos of the merchandise and offers before you shell out the harmony. Q3. What is your phrases of supply?A: EXW, FOB, CFR, CIF, DDU. This autumn. How about your shipping and delivery time?A: Typically, it will take thirty to 60 days right after getting your advance payment. The distinct shipping and delivery time relies upon on the things and the quantity of your buy. Q5. Can you create according to the samples?A: Sure, we can produce by your samples or complex drawings. We can construct the molds and fixtures. Q6. What is your sample coverage?A: We can provide the sample if we have completely ready elements in stock, but the customers have to shell out the sample cost and the courier expense.Q7. Do you take a look at all your items just before shipping and delivery? A: Of course, we have one hundred% take a look at before delivery Q8: How do you make our business lengthy-term and great romantic relationship?A:1. We hold good good quality and competitive cost to ensure our clients gain 2. We respect every single consumer as our pal and we sincerely do organization and make friends with them, no make a difference the place they come from.

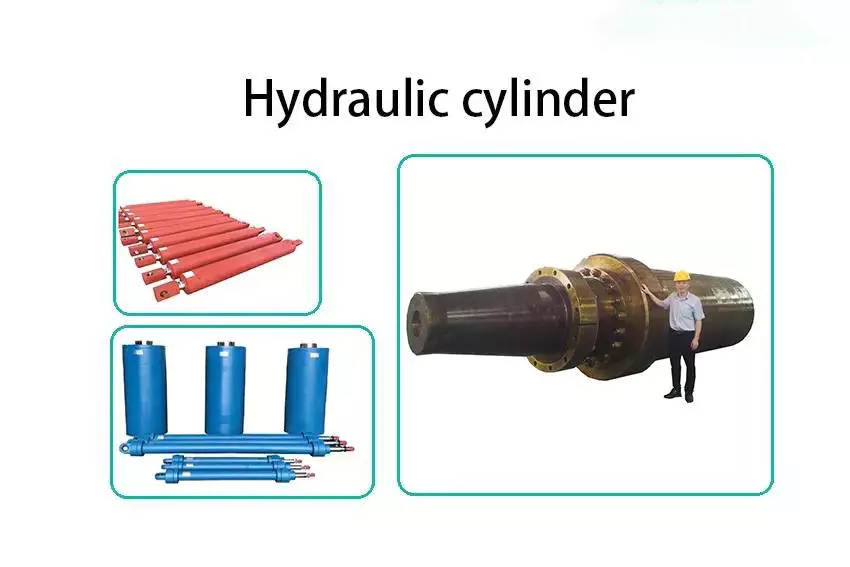

Choosing Hydraulic Cylinders

Typically, hydraulic cylinders are used in applications such as manufacturing machinery, construction equipment, and civil engineering. They are also used in elevators and other applications where the use of a mechanical actuator is necessary.

Piston seals

Choosing the correct piston seals for hydraulic cylinders can help to ensure the proper operation of the cylinder. Seals are designed to keep fluids and contaminants from flowing across the cylinder. However, external factors can affect their performance. In order to choose the right seals, it’s important to understand the different types.

There are two basic piston seal types. One is a double acting seal that maintains pressure on both sides of the piston. The other type is a single acting seal that maintains pressure on only one side of the piston.

Double acting piston seals are typically made of a slide ring. They maintain the pressure in a hydraulic cylinder and allow the ram to move in a controlled direction. The slide ring is normally made of a plastic material. However, it is important to select a material that is suitable for the fluid pressure that is expected.

Single acting cylinder seals are designed for cylinders where one side of the piston is under high pressure and the other side is under low pressure. These seals are usually designed to provide the best sealing characteristics.

In addition to the seal, it is important to select the right guide. A guide is a metal strip or ring that keeps the piston and the piston rod radially centered in the cylinder assembly. This guide also keeps metal-to-metal contact between the two components.

For high-pressure applications, it is recommended to use piston seals made from PTFE. These seals can withstand temperatures up to 800 degrees Celsius. They have less friction than rubber seals and are also resistant to abrasion. However, they are not as durable as thermoplastic elastomers.

The seals are designed to maintain a constant pressure for a longer period of time than other materials. In addition, they are resistant to tearing, and they stand up to high use.

Coatings for hydraulic cylinders

Various coatings for hydraulic cylinders are available in the market. The main purpose of these coatings is to provide protection against physical and chemical attacks. These coatings are usually applied externally or internally.

Plasma spray is one of the most common surface modification methods. It combines flame and arc spray to deposit metallic or ceramic materials onto the surface. This process improves the operating characteristics of actuators. It is also useful in repairing damaged surfaces.

Another popular surface treatment is liquid nitrating. It produces a hard iron nitride layer that has excellent surface hardness. It also provides a good surface resistance. It can be used as a thermal barrier coating on stationary gas turbine blades.

Hard chrome over nickel coating is also a common type of coating for hydraulic cylinders. It provides good corrosion resistance and abrasion resistance. It is plated onto the surface and then polished.

Another popular surface modification method is thermal spray. It uses engineered materials to deposit metallic or ceramic materials onto the surface. It is a cost effective solution to surface enhancement. It also eliminates the need for costly replacement parts.

In addition, WC-CoCr coatings provide good wear resistance and corrosion resistance. These coatings are particularly useful for parts that are subjected to harsh working conditions.

Ceramic plating is mostly used in the aerospace and military industries. It also reduces friction and provides heat shielding. It can also be used as an alternative to hard chrome coatings.

The most important mechanical properties are the hardness, yield strength and the tensile strength. The material selection should be based on the shape and dimensions of the object being produced. This article will discuss the most commonly used materials and give an overview of the most effective surface modification methods.

Double-acting cylinders

Basically, hydraulic cylinders are used in a variety of applications, including engineering, industrial furnaces, and lift shafts. They are also used in subsea environments, shipbuilding, and oil & gas.

A double-acting hydraulic cylinder is a type of hydraulic cylinder that combines the best features of a single-acting cylinder with some additional advantages. These benefits include higher force, greater flexibility, and more control. Double-acting hydraulic cylinders are generally used in high-powered applications, such as lift shafts, excavation equipment, and robotics. They are also used in mobile applications, such as earthmoving equipment.

The main difference between single acting and double-acting hydraulic cylinders is the way the piston is moved up and down the cylinder bore. Double-acting cylinders use hydraulic fluid to apply pressure on both sides of the piston rod.

Another advantage of double-acting hydraulic cylinders is their ability to extend and retract without the need for an external force. In contrast, single acting cylinders require an external source to move the piston.

Double-acting hydraulic cylinders are more expensive than single-acting cylinders. This is because they have a larger housing and require more dedicated maintenance. They are also more costly to buy.

However, they are also more accurate and efficient. Double-acting cylinders work faster and can be used in virtually any application. They are also better for industrial tasks, such as lifting merchandise off conveyor belts. They can also work in an angle, and they are suitable for mobile applications.

In addition to their performance, double-acting hydraulic cylinders are more likely to be ISO compliant than single-acting cylinders. They also offer more design options.

Depending on the needs of the application, a double-acting hydraulic cylinder may be more expensive than a single-acting cylinder. This is because the piston seal must be designed to work with the fluid. The seal material is generally rubber or a rubber/fabric composite.

Stainless steel cylinders

Stainless steel hydraulic cylinders are used in numerous industries. They are known for their durability and rust resistance. They are used in industrial hydraulics applications, as well as in the food and beverage processing industry. They also help processing facilities meet industry standards.

Stainless steel hydraulic cylinders are made of a stainless steel alloy that contains at least 10% chromium. The chromium oxide forms a thin layer on the steel’s surface, contributing to its corrosion resistance. The alloy also develops a non-porous surface that prevents bacteria from lingering. It also contributes to the steel’s ability to self-repair.

Stainless steel hydraulic cylinders are widely used in the food and beverage processing industry. They are particularly useful for moving heavy loads. They can withstand frequent cleaning operations. They also provide excellent strength. They are commonly used in chocolate molding machines and cold press juicers.

Stainless steel hydraulic cylinders are available from Maverick Machine & Hydraulics. They can be customized to meet your specifications. They can be manufactured with a satin finish or a streamlined design. They can also be custom colored. The manufacturer will provide full service and a competitive price.

Hydraulic cylinders are used to push, pull, or push-pull heavy loads. They are designed to withstand extreme temperatures. They are also available in single and double-acting configurations. They are commonly used in pharmaceutical, food, chemical, and marine applications. They are also used on coastal power generation plants and pipeline risers. They are also used in water treatment plants. They can also be used on oil platforms.

There are two types of hydraulic cylinders, which are single-acting and double-acting. The single-acting type has a single fluid chamber, while the double-acting model has more fluid in the pressurized chamber. The single-acting cylinder is more affordable to maintain and easier to control.

Pivot rod style cylinders

Choosing hydraulic cylinders requires a great deal of attention to detail. You will need to consider the following factors: cylinder length, rod size, rod seals, bearing loads, and the type of cylinder you need.

Hydraulic cylinders are used in a variety of applications, such as lifting and lowering buckets, as well as jack knifing and metal sheet shearing machines. They are also used in hydraulic bending machines and earth-moving equipment.

The main sleeve or barrel of a hydraulic cylinder extends to its maximum stroke. It can be either single or double acting, and can be either stationary or pivoting. This allows a cylinder to move a load in a straight line or a circular path.

Cylinders have a variety of mounting styles, including clevises, flanges, and side mounts. Flange mounts are generally used in force-transfer applications where the cylinder must be parallel with the load. Flanges come in several shapes and sizes, including a square flange, a rectangular head, or a cap. Aside from transferring load, they also absorb force along the cylinder centerline.

Cylinders have a variety and range of seals, which are used to prevent hydraulic fluid leakage past the interface. These seals are made of various materials, including metal and elastomeric seals. The materials used for these seals depend on the application. These seals also vary in terms of pressure, temperature, and temperature changes.

Clevises and flanges are two common mounting styles for hydraulic cylinders. They are used to provide structural support for bolts. These mounts also work to absorb force along the cylinder’s centerline. These mounting styles have less rod bearing loads than other types, but they must be properly aligned with the load.

editor by czh 2023-06-27