Guarantee: 1 a long time

Personalized assistance: OEM, ODM, OBM

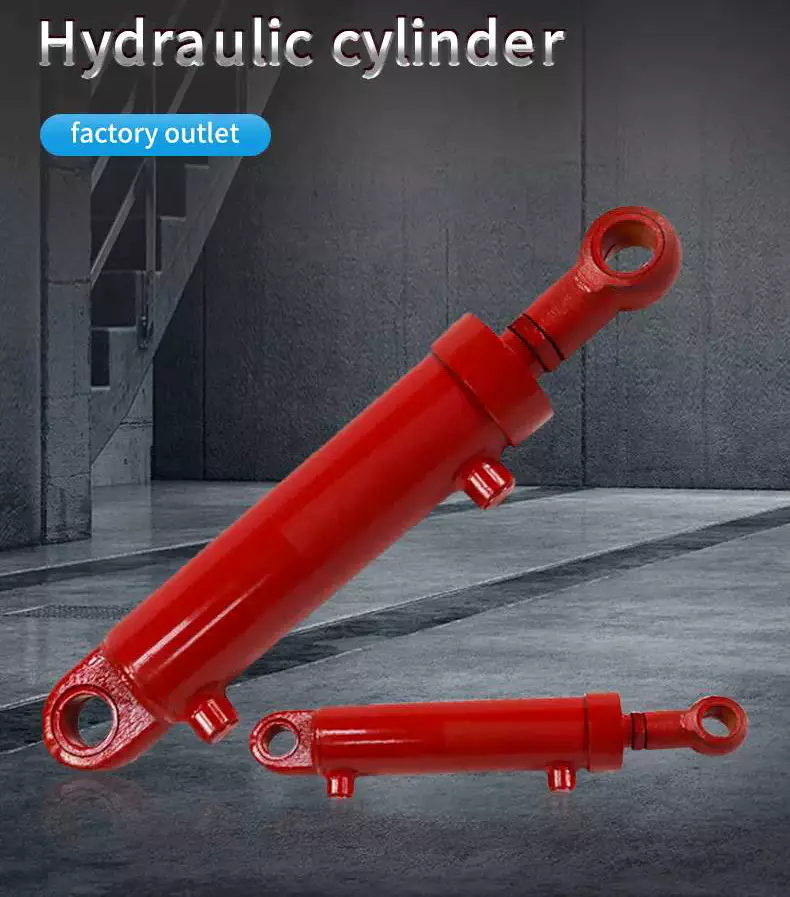

Product title: Components For Hydraulic Cylinder

Operating Pressure: 10-35 Mpa

Port Size: Buyer Need

Application: Engineering Building Development Cylinder

Substance: twenty#/45# Steel

Deal: Buyer Need

Port: HangZhou

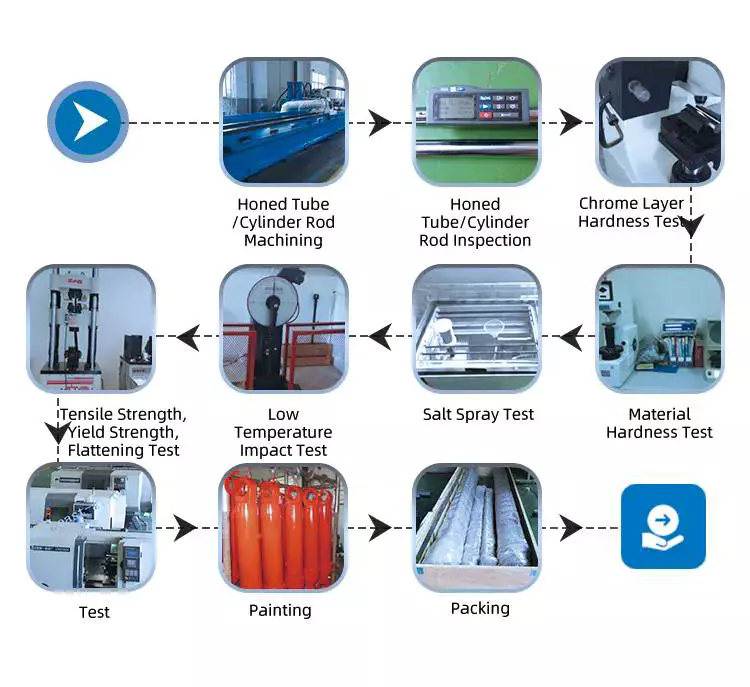

Merchandise Description Large Top quality CNC OEM Machining Provider

| Provider | CNC Turning, CNC Milling, Laser Cutting, Bending, Spinning, Wire Chopping, Stamping, Electrical Discharge Machining (EDM), InjectionMolding | |

| Resources | Aluminum: 2000 sequence, 6000 series, 7075, 5052, and many others. | |

| Stainless steel: SS316, SS316L, seventeen-4PH, and so on. | ||

| Brass: C360, H59, H60, H63, H65, H68, 6703 2rs 6703zz S6703 S6703zz CZPT skinny section deep groove ball bearing H70, Bronze, Copper | ||

| Metal: 1214L/1215/1045/4140/SCM440/40CrMo, etc. | ||

| Area Therapy | Anodized, Bead blasted, Silk Display, PVD Plating, Zinc/Nickel/Chrome/Titanium Plating, Brushing, Painting, Powder Coated,Passivation, Electrophoresis, Electropolishing, Knurl, Laser/Etch/Engrave etc. | |

| Lead Time | one-2 months for samples, 3-4 weeks for mass production | |

| Quality Assurance | ISO9001:2015, ISO 13485:2016, SGS, RoHs, TUV | |

| Payment Phrases | Trade Assurance, TT/ PayPal/ West Union | |

| Processing | CNC turning, CNC milling, Substantial High quality Robust Load-bearing Building Welld Tower Crane CNC machining, Grinding, EDM wire chopping | |

| Service Venture | To offer manufacturing design and style, manufacturing and complex support, mould improvement and processing, and many others | |

| If you have any questions, please make contact with our consumer support. For the duration of the obtain method, we can fulfill all your demands. | ||

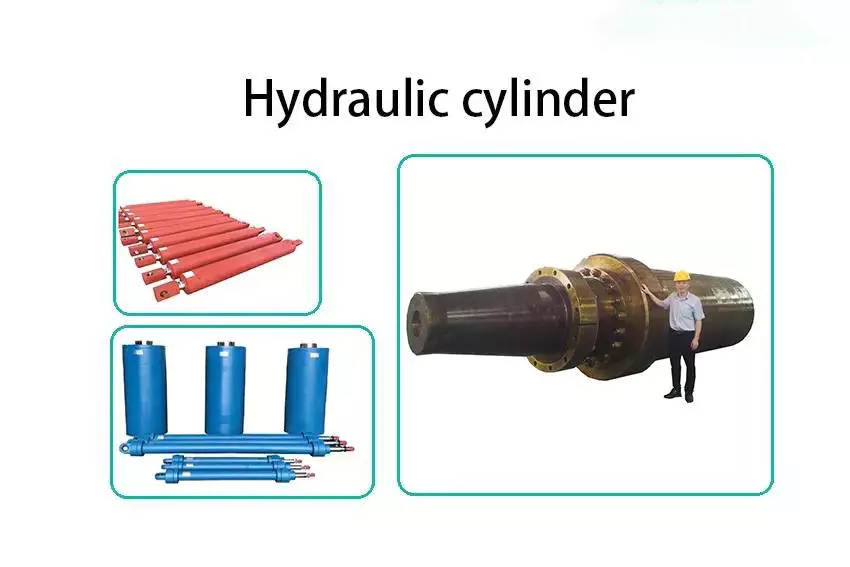

Different Types of Hydraulic Cylinders

Generally, hydraulic cylinders are used in manufacturing machinery, construction equipment, and civil engineering. They are also used in elevators, and to provide unidirectional force.

Single-acting vs double-acting

Whether you are deciding on single-acting vs double-acting hydraulic cylinders for your application, it is important to understand the differences between the two so that you can make an informed decision. There are a number of advantages and disadvantages to both types, so choosing the right one for your application can be difficult.

Single-acting cylinders use compressed air to force the piston rod to extend, while double-acting cylinders use hydraulic fluid to actuate the piston rod. The piston rod is then returned to its original position after the pressure is released.

Double-acting cylinders have two ports that connect to the piston rod. Hydraulic fluid is pumped into the first port to extend the piston rod, while the second port provides pressure to the piston rod to retract it. The fluid exits through the other port. The cylinder’s pressure can be increased by increasing the fluid flow through the cylinder. This can also increase the speed of the cylinder.

Single-acting cylinders are cheaper to manufacture and install than double-acting cylinders. They are also easier to maintain. They also use fewer seals and valves than double-acting cylinders. However, they have a limited amount of control during operation. They also require a control system consisting of position valves. They are commonly used in reciprocating engines, hydraulic rams, and pumps. They are also useful for lifting equipment, lift shafts, and steering mechanisms.

Single-acting cylinders also have a certain rest state. If the power goes out, the cylinder will return to its resting position. However, if the springs wear out or the internal components break, the end of the stroke may be uncertain. This can be dangerous during power outages.

Unlike single-acting cylinders, double-acting cylinders provide stronger control and flexibility. They can be used in virtually any machine application. They are particularly useful for robotics, medical, and industrial tasks. They also provide more design options. They are also more energy efficient, but have a higher cost. They are also often more durable than single-acting cylinders.

Double-acting cylinders are available in a variety of sizes and designs. They are often used to control steering in excavators and TLBs. They are also used to move merchandise off conveyor belts. They are available in lightweight and high-tonnage models. They can also be used to control booms on TLBs. They have ISO standards compliance. They can also be converted to single-acting cylinders, if desired.

Single-acting cylinders are generally cheaper to manufacture and install, but they do not offer the same level of control as double-acting cylinders. They are also easier to repair, so they are often used in fixed applications. They are also available in a variety of sizes, including low-height models. They are also available in a variety or styles, including telescopic hydraulic cylinders. They are also available in many different applications, including lifting equipment, dump trailers, and platform truck trailers.

Stainless steel vs steel

Stainless steel and steel hydraulic cylinders are both durable materials that offer many benefits to users. These hydraulic cylinders are used in a number of different industries, including food and beverage processing. The food processing industry has very strict guidelines for cleaning equipment, so stainless steel hydraulic cylinders are preferred.

Stainless steel is a material that is non-porous, which means that it prevents bacteria from settling on the surface of the cylinder. This is important because food processing equipment needs to be clean to ensure the safety of consumers. A stainless steel cylinder is also a good choice for areas that are susceptible to corrosive chemicals.

Another advantage of stainless steel is the tensile strength of the metal. This makes it perfect for hydraulic applications that produce high temperatures. It also has excellent heat resistance. While the material can easily withstand the heat, it may not be as durable in humid or wet environments. In these conditions, nitriding is used to increase the surface hardness of the metal. In addition, special construction may be used to reduce oxidation.

While stainless steel hydraulic cylinders are used in many industries, the food processing industry is among the most common. Food processing equipment is heavily used, and stainless steel ensures that components will last. This is particularly true in environments that frequently require washing.

One of the best features of stainless steel is its resistance to corrosion. Its alloy composition contains at least 10% chromium, which helps create a thin layer of chromium oxide. This oxide layer protects the metal from rusting, and it also improves the self-repairing qualities of the material. The alloy also contains molybdenum, which creates a non-porous surface. This is important in food processing equipment because it prevents food particles from adhering to the surface. It also helps eliminate downtime due to contamination.

Stainless steel hydraulic cylinders are also durable, and they can withstand frequent cleaning. They are also used in equipment that is washdown-ready. The cylinders’ surfaces may be polished to achieve a satin finish, which is noticeable by fine, uniform grit lines across the stainless steel. The surface may also be coated in a variety of paints. This helps prevent bacteria from settling on the surface of the metal, and it also prevents food particles from sticking to the cylinder.

Another benefit of stainless steel hydraulic cylinders is that they can be used in environments that are highly contaminated with corrosive chemicals. They are especially suited for offshore oil rigs, where they are exposed to aqueous corrosion. They are also favored for use in the metals industry, as well as in pulp and paper mills. They are also used in a number of other applications, including cold press juicers and chocolate molding machines.

Stainless steel hydraulic cylinders also tend to have a streamlined design. They also may have end caps, which help prevent catch points and mounting holes. This prevents bacteria from settling on the surface and helps to eliminate downtime due to contamination.

Coating

Whether you are an engineer or an owner of hydraulic cylinders, you know the importance of protecting your components from corrosion and wear. Hydraulic cylinders are designed to perform in high temperatures and high pressures, and they can be damaged by environmental conditions or mechanical deformations. The proper coating of hydraulic cylinders is essential to reduce wear and tear, and reduce the risk of corrosion and adhesion. If your hydraulic cylinders are damaged, the result can be expensive repairs.

Hydraulic cylinders are used in a variety of industries, including automotive, aerospace, marine, oil and gas, and offshore. The cylinders are primarily designed for high cycle applications, which can increase wear. However, they can be used in other types of applications as well.

There are several coating methods available on the market. One process is the electro galvanizing process. This process involves the use of electricity to deposit a zinc coating on the hydraulic cylinder. This coating can protect the cylinder for a lifetime. There are several methods to choose from, depending on the thickness of the coating.

Another method is the electro-plating process. This method has been used to coat hydraulic cylinders for offshore applications. However, the European Union nearly banned the process due to environmental concerns. The process is also used to coat corrosion resistant nickel-based alloys. Using this technology allows companies to coat hydraulic cylinders without having to involve a coater. The process is also easy to integrate.

One alternative coating process is thermal spray. This process uses engineered materials to deposit metallic or ceramic materials onto the surface. The spray is then used to enhance the surface, restoring damaged hydraulic rods, or preventing future breakdowns. Thermal spray also increases wear life.

Another coating process is the hard chrome over nickel process. Traditionally, hard chrome plating is used on hydraulic cylinder rods. However, this method has largely fallen out of favor. The main reason for hydraulic cylinder failure is corrosion of the piston rod surface. If your cylinder is exposed to rust, you may have to replace the cylinder barrel. Using a hard chrome over nickel coating can help to prevent corrosion.

Another coating process is a nickel sub-coating. Similar to a chromium trioxide-based coating, this provides corrosion resistance. It also provides a hard surface.

These coatings can be used in various hydraulics applications, including ball valves, brake pistons, and loader cylinders on compact tractors. Despite the fact that the process provides adequate corrosion resistance, some branches will not accept it, because of the nickel leaching that may occur. Unlike a chromium trioxide-based coating, a nickel sub-coating can be used on oil-based actuators, which may be prone to wear.

There are many types of hydraulic cylinders. Each type is designed for a different application. They all have different surface properties. These properties affect seal performance, leakage, and friction. If your hydraulic cylinders are not properly coated, they may rust, damage seals, and wear out prematurely.

editor by czh 2023-06-27