Guarantee: 1 Year

Showroom Location: None

Force: 16Mpa

Weight: 75

Energy: Hydraulic

Dimension(L*W*H): 750.600.285

Rod Diameter: relies upon on the product

Greatest Stroke: 300mm

Outer Tube Diameter: is dependent on the product

Inner Tube Diameter: depends on the model

Merchandise name: Hydraulic Dump Hoist cylinder

Application: Tipping Trailer

Type: Double Performing

Mounting Fashion: Mounting brackets

Seal: Hallite

Physique Material: Metal

Voltage: 12VDC 24VDC

Carry ability: 3-ten tons

Deal: Plywood package

MOQ: 1 sets

Packaging Particulars: Plywood pallet

Port: HangZhou

Hydraulic scissor hoist kit The complete program of this Hydraulic Hoist Package which includes:one set Frame1 piece Hydraulic Cylinder1set Hydraulic Electrical power Unit2 parts Hydraulic Hoses with connectors Relevant accessoriesWork: Up &Down by hydraulic handle, CZPT Kits 3 point linkage system agriculture part double performing functionInstall placement: Medium position below trailer’ Precision Aluminum alloy set helical beam adaptable shaft coupling s bodyFixed component: Mounted body with 4 tiny brackets AC 220V 15W 40W 60W 70W 100W Ceiling Air Conditioner Motor Flexible selection load potential: Bare minimum 3ton, Maximum 10ton

| dump trailer hoist | reduced profile hydraulic dump hoist | dump trailer electrical power hoist | trailer hydraulic scissor hoist kit | dump bed kit for trailer |

| tipping trailer hydraulic hoist kit | three ton hydraulic scissor hoist package | hydraulic scissor hoist | hydraulic cylinder for trailer | KRM hydraulic hoist |

| double acting hydraulic hoist package | reduced profile dump trailer hoist kit | hydraulic cylinder elevate package | dump trailer cylinder | hydraulic cylinders |

| 3 ton dump trailer hydraulic scissor hoist package | scissor carry hoist | dump trailer scissor hoist | hydraulic cylinder raise | energy hoist |

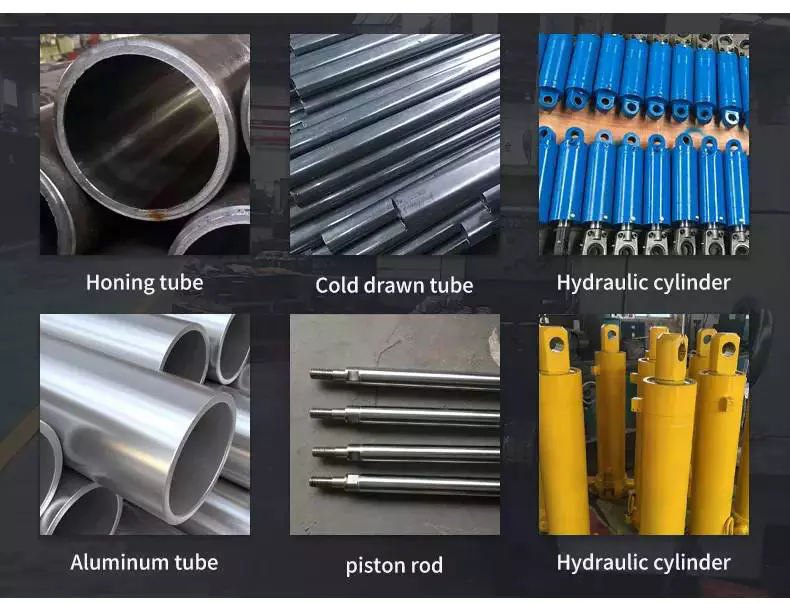

Choosing Seals and Mounting Options for Hydraulic Cylinders

Basically, a hydraulic cylinder is a mechanical actuator. It’s used in many different industries including construction, manufacturing, and civil engineering. These cylinders are designed to provide a single, unidirectional force.

Common seals

Choosing the right seals for hydraulic cylinders is crucial to the overall performance and durability of the system. Seals must be able to resist a wide range of temperatures, and also withstand pressure. Seals must also be compatible with the hydraulic fluid used in the system.

Seals can be made from a wide variety of materials. These materials include rubber, thermoplastics, metal, leather, and felt. These materials all serve different purposes. Some seals are designed to add strength to the cylinder, while others are designed to prevent leakage.

Rubbers are commonly used for dynamic seals in the fluid power industry. They are characterized by high tensile strength, high stiffness, and resistance to abrasion and weathering. They can handle a wide range of temperatures, and can withstand water, ozone, and oxygen. They are also resistant to tearing and abrasion.

Metal materials are used for rod and piston seals. They can be made from bronze, carbon steel, stainless steel, or aluminum. They can also be galvanized for added strength. Metals can be plated for oxidation protection. They may also be bonded with thermoset materials to provide enhanced sealing capabilities.

Thermoplastic elastomers provide excellent resistance to wear and pressure. They are also characterized by elasticity and flexibility. These materials have high tensile strength and low compression set. They are also resistant to abrasion, tearing, and abrasive wear. They can be bonded to rigid plastics to increase their durability and sealing performance.

Seals are used in hydraulic cylinders to protect the cylinder from contaminants and dirt. They also prevent leakage of the hydraulic fluid. Seals can be used in higher pressure systems, though they may not be suitable in low-pressure systems. Seals may also need to be compatible with additives used in hydraulic fluids.

Piston seals

Choosing the right piston seals for hydraulic cylinders is a key factor in obtaining the best performance for your application. Seals should be able to provide reliable sealing without leakage, and prevent contaminants from entering the cylinder. A wide range of materials are available for piston seals, including plastic, rubber, and fluorocarbon. Choosing a seal that meets your application’s mechanical, chemical, and temperature requirements is also important.

Polytetrafluoroethylene (PTFE) piston seals are highly recommended. They offer excellent resistance to wear and a high temperature range. This material is also compatible with many media. They are available in a wide range of seal designs, including single-acting and double-acting. They are also available with or without anti-extrusion rings.

A wide range of piston seals are available for hydraulic cylinders. Double-acting seals, for example, contain pressure on both sides of the piston without leakage. They are typically manufactured from Turcon(r) polytetrafluoroethylene, which is specially engineered for fluid power applications.

Single-acting piston seals are designed to contain pressure on one side of the piston. They can be symmetrical or asymmetrical. Asymmetrical seals include single-acting metric U-Cup designs, which can be manufactured from a wide range of materials, including fluorocarbon.

Double-acting piston seals provide the best sealing capacity of double-acting hydraulic cylinders. These seals are capable of sealing dynamic pressure on both sides of the piston, providing maximum sealing capacity for a wide range of cylinder applications. They are also designed to maintain low friction.

Choosing the right piston seals for hydraulic applications is important to reduce the risk of damage to a machine. Hydraulic cylinder seals are designed to retain hydraulic fluids and to exclude both solid and liquid contaminants. If a seal is leaking, or not exerting enough pressure, the pressure can drop, reducing the capacity of the cylinder to perform its work.

Rod seals

Choosing the right hydraulic rod seal is an essential part of maintaining the pressure in a hydraulic system. In addition, the seal must provide a thin layer of lubrication to the piston rod to prevent corrosion. Rod seals come in many different sizes and designs. They must also withstand the pressures generated in position-holding operations.

The most common materials used for hydraulic rod seals are PTFE-based materials. These materials are specifically engineered for fluid power applications and offer outstanding temperature performance.

These seals are designed to reduce friction losses, which can be 30 to 70 percent. This helps to minimize the impact on operating budgets and the environment.

In addition, rod seals can also be used as secondary seals in a sealing system. A secondary seal works in conjunction with a primary seal to reduce the load placed on the primary seal. This can also reduce the amount of pressure peaks in the system.

The primary seal and the secondary seal work together to ensure that the cylinder leaks to the exterior, and that the piston remains radially centered in the cylinder assembly. The primary seal is designed to withstand high operating pressures. It is usually made of Turcon(r) PTFE-based material.

When a rod seal leaks, it can be dangerous. It can cause problems with the hydraulic system, as well as environmental concerns. The best solution is to choose a seal that has a backup ring. This will ensure that the seal is able to withstand side-loading, while still allowing lubrication to pass through.

Rod seals for hydraulic cylinders can be made of a variety of materials. The choice of material must be made according to the pressure and temperature requirements of the hydraulic system. The material should also be chosen based on the type of fluid being used.

Welded connections

Whether you’re buying hydraulic cylinders for a new application or repairing a cylinder, you need solid welds to prevent joint failure. Incorrect welding can cause distortion and residual stresses that will ruin your system. A certified welder can create an effective weld between dissimilar metals.

In the field of hydraulic repair, four welding processes are the most common. They are friction welding, MIG (stick welding), friction welding, and friction welding with a laser beam.

Tie rod style hydraulic cylinders use high-strength threaded steel rods. They are usually off-the-shelf items. They are usually used in industrial factory applications. They are also prone to stretching over their service life.

Welded hydraulic cylinders are designed for rugged industrial environments and perform well in tough conditions. They have a more complex design, but are generally a better solution for most applications.

Cylinders made with welded connections have a higher service life than those made with tie rods. Welded cylinders have less distortion and heat than tie rod cylinders. They also have more options for customising their design.

For example, you can have welded hydraulic cylinders with special features, such as grease zerks, and special features added to the rod rod. In a heavy-duty application, you can add a piston seal to eliminate leaks. During repair, you may also want to add mounting attachments to the piston rod.

In a heavy-duty application, you’ll find that welded cylinders have a larger bore size. This allows for more pressure and force. You can also find heavy-duty cylinders that can withstand a 3,000 pound force per square inch pressure.

You’ll find that welded cylinders are more expensive than tie rod cylinders. They also require a different set of tools. These cylinders are also more difficult to repair.

Mounting options

Choosing the correct mounting options for hydraulic cylinders is important for minimizing accelerated wear and maintaining a cylinder’s best performance. A wide variety of mounts are available to suit a wide range of applications. Each system has its own advantages and disadvantages.

A flange mount is a fixed centre-line of the cylinder. It provides good strength, rigidity and stability. It is a good choice for stationary cylinders. Flange mounts are especially useful for applications that require straight-line force transfer. They are not as tolerant to misalignment as other cylinder mounts.

The clevis mount is one of the most common mounting options for hydraulic cylinders. It is attached to the cylinder cap, which is usually the end cap, or cylinder head. These mounts are usually used in mobile hydraulics. They offer good strength, rigidity and stability, but they are not as tolerant to misalignment as other cylinder mounts.

Pivot mounts are also available for hydraulic cylinders. They allow the cylinder to pivot in a single range of motion. They are available with a cap spherical bearing. They are best for short-stroke applications. Pivot mounts are also available with an intermediate fixed trunnion. They provide stability, strength, and a centerline mounting advantage.

Centerline cylinder mounts are a good choice for ensuring longevity. They provide support along the centerline, which helps absorb forces in a straight line. They are also best for applications with high internal pressure. They can be used in conjunction with tie-rod mounts to support the rods in compression.

Clevis bracket cylinder mounts provide support against side loading, which is important in a number of applications. These mounts can be installed into standard bore sizes, and have a double-tang design for improved rigidity and strength. They also have snap rings and cotter pins to hold the mounting bracket in place.

editor by czh 2023-07-03