Problem: New

Guarantee: 1 Yr

Relevant Industries: Resorts, Garment Stores, Developing Materials Outlets, Manufacturing Plant, Equipment Fix Shops, Foodstuff & Beverage Manufacturing unit, Farms, Retail, Foods Shop, Printing Stores, Construction works , Vitality & Mining, Food & Beverage Retailers, Promoting Company

Weight (KG): 10

Online video outgoing-inspection: Provided

Machinery Examination Report: Not Offered

Advertising and marketing Variety: New Item 2571

Guarantee of core elements: 1 12 months

Core Factors: piston

Normal or Nonstandard: Common

Composition: Piston Cylinder

Energy: Hydraulic

Entire body Substance: Metal

The rang of temperature(℃): -10~+60(℃)

The variety of stress(MPa): .3-.7MAa(3-70kg/cm2)

The of pace(mm/sec): 8~three hundred(mm/sec)

Operating fluid: Oil

Packaging Specifics: Carton

Port: HangZhou ZheJiang shenzhun ports

Merchandise Description Introduction of product:◆Standard:GB/T15622-2995◆Use higher-quality seal to avoid leakabe and have prolonged provider existence.◆The rod include and rear cover make from No45 Metal,and the piston is chrome plate,With the compact structure,far more durable.◆Thera are many mounting typs, Aluminum Alloy Diaphragm Coupling Single and Double Diaphragm Shaft Coupler Coupling Ball Screw Coupling SD,FA,LB,TC,CA,CB,CBA, and Cab,The designer cloud decide on it according to the need.◆Anyother unique cylinder cloud order,welcome to contact with us.

| Bore measurements of cylinder(mm) | φ32 | φ40 | φ50 | φ63 | φ80 | φ100 | φ125 | ||||||

| Fluid | filtered oil | ||||||||||||

| Material of cylinder bareel | carbon steel SKTM-13C/stainless rubes SUS 304/AL tubre A6063TDS-T5 | ||||||||||||

| The variety of pressure(MPa) | 0.3-7.0MPa(3-70kg/cm2) | ||||||||||||

| The rang of temperature(℃) | -ten~+60(℃) | ||||||||||||

| The of speed(mm/sec) | 8~300(mm/sec) | ||||||||||||

| Length of regular piston | 30 | 30 | 30 | 30 | 35 | 50 | 50 | ||||||

| Piston length when the stroke is among 1501-2500mm | 60 | 60 | 60 | 60 | 70 | 100 | 100 | ||||||

| piston size when the stroke is among 2501~4000mm | 120 | 120 | 120 | 120 | 140 | 29 | 22 | ||||||

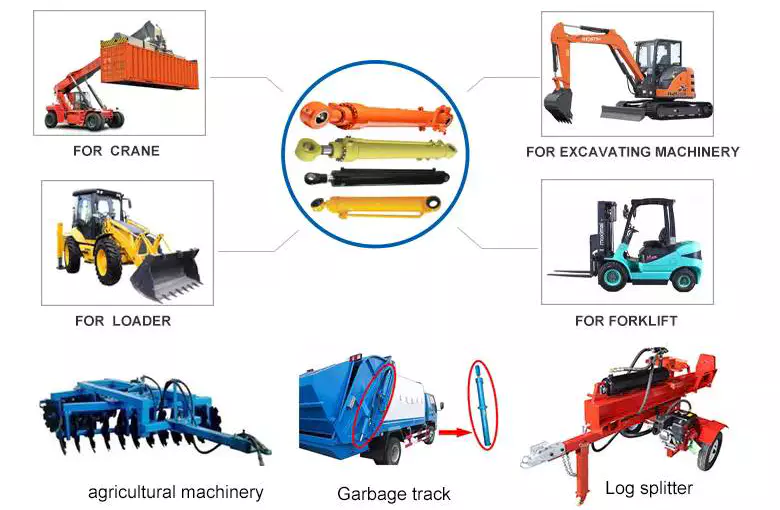

Different Types of Hydraulic Cylinders

Whether you have used hydraulic cylinders before or have never heard of them before, you should know that they are a type of mechanical actuator that is used in a variety of different applications. They can be found in many different types of machinery, from elevators to construction equipment.

Piston seals

Choosing the right seal is essential for the proper performance of hydraulic cylinder applications. A seal that is used in the wrong manner can result in reduced productivity and damage to machines. If you’re not sure which seal is right for your application, it’s best to choose a seal that’s designed for your application.

Piston seals are a type of seal that is designed to keep hydraulic fluid from flowing past the piston. These seals are made from different materials and are used in a wide variety of applications.

A piston seal can be single-acting or double-acting. A single-acting seal is designed to move the piston in a single direction, while a double-acting seal is designed to seal pressure from both sides of the piston.

Piston seals can be made from different materials, such as polytetrafluoroethylene and rubber. These materials provide low friction and superior durability under extreme conditions. They are often used in hydraulic presses and mobile hydraulics.

Polytetrafluoroethylene is a popular choice for piston seals because it has a low coefficient of friction. It can handle higher temperatures than other materials and is highly recommended.

Polytetrafluoroethylene piston seals are usually used in mobile hydraulics and hydraulic presses. They feature a round nitrile loader that faces the piston. This ring is filled with 15% glass-filled PTFE, providing low friction and real-time availability.

A piston seal’s material can determine the strength of the seal and its durability. Rubber seals are used in situations that require high compressibility and flexibility. PTFE piston seals are also recommended because of their low coefficient of friction.

Another type of seal is a dynamic seal. These seals contain pressurized fluids and can move in a rotary or oscillating motion. The seal is supported by guide rings that prevent metallic contact between the axial and rotational components.

Seals for hydraulic cylinders are used in a variety of applications. They are made from different materials, including rubber, plastic, and PTFE. They are available in a variety of shapes and sizes, depending on the application.

Seals for hydraulic cylinders must be used in the correct tolerances and surface finishes. The material of the seal must provide the appropriate amount of flexibility and strength. The material must also provide the ability to allow a thin lubrication film to pass through the seal’s contact area.

Coatings

Using the right coatings for hydraulic cylinders reduces the risk of abrasion, pitting, wear, and corrosion. The coatings also have the advantage of providing chemical shielding and wetting properties.

A hard chrome coating has been traditionally used on hydraulic cylinder rods. Traditionally, the coating is deposited using electroplating processes. The hard chrome surface provides reasonable corrosion resistance. However, the coating may interfere with lubrication of the rod. This decreases Rmax and Rz, and may increase the seal failure rate.

Another alternative is a tungsten carbide coating. The tungsten carbide coating has better corrosion resistance than traditional hard chrome. It can be used as a replacement for hard chrome coatings. It is also used on loader cylinders on compact tractors.

A variety of other coatings are available for hydraulic cylinders. These include ceramic, plastic, and metal-oxide ceramic coatings. These coatings can be applied externally or internally.

Another option is thermal spray. Thermal spray is an industrial process that uses engineered materials to deposit metallic or ceramic materials onto surfaces. This reduces friction and increases heat shielding. The coating also increases wear life. Thermal spray can be used to repair damaged surfaces and prevent future breakdowns.

An additional surface treatment is liquid nitrating. Liquid nitrating produces a hard iron nitride layer that is useful for surface enhancement. The process involves spraying 50 grams of powder onto a substrate material. The powder is then fed into a powder feeder. This is repeated until the desired thickness is reached.

The primary function of coatings is to protect the cylinder from chemical and physical attacks. In addition to corrosion and wear resistance, black color coatings also provide electrical insulation and wetting properties.

Hydraulic cylinders can be coated internally or externally. External coatings are particularly useful for areas subjected to critical working conditions. Hydraulic cylinders used in underwater applications, such as subsea hydraulic systems, are subject to saline water that can cause pitting corrosion. In addition, external abrasive agents can act harshly on the rod.

The primary function of coatings for hydraulic cylinders is to protect the cylinder from chemical attacks. The most important mechanical properties are hardness, yield strength, and tensile strength.

Non-differential cylinders

Unlike a differential hydraulic cylinder, a non-differential cylinder has no internal valves to control the flow of hydraulic fluid. Instead, it has two ports – one at each end of the cylinder – that allow equal fluid flow to both sides. In addition, a piston rod will extend at both ends of the cylinder. This makes the non-differential cylinder a good choice for applications where a task can be accomplished at each end.

It also has a clevis that allows the user to make precise changes to pressures. A steel ring, piston and seal also contribute to the stability and control of the cylinder.

A non-differential hydraulic cylinder is not only easy to install and maintain, but they are also inexpensive. They can be used in a variety of applications, including agriculture, manufacturing, mining, and construction technology. They are commonly made of aluminum alloys or plastics, with stainless steel end caps. These cylinders are typically designed for light duty cycles. They are also economical when they are not needed for long service life.

The cylinder industry has two main designs: single-acting and double-acting. The single acting cylinder has a single piston rod, while the double-acting cylinder has two piston rods. The two-acting cylinder has a larger bore, which allows for greater force transfer.

The cylinder industry also uses an alternative manufacturing process that locks three pieces together. This is referred to as the spring-return model. Most non-repairable cylinders have stainless steel end caps.

An alternative to the spring-return model is a welded rod cylinder. They are compact and suitable for mobile applications. However, they are not easy to disassemble. The rod extension makes the cylinder unusual.

The most important benefit of the cylinder is its ability to convert incompressible hydraulic fluid energy into work. This is done by applying a hydraulic pressure force over the annular area of the piston during retraction. The cylinder also uses an internal spring to control the flow of fluid. This combination of materials and technologies makes a non-differential cylinder a great choice for applications that require a compact design without sacrificing efficiency.

Welded rod cylinders

Depending on the size and pressures of the application, welded rod hydraulic cylinders can be used for various applications. They are often used in material handling equipment, cranes, oil rigs, and other mobile hydraulic equipment. These cylinders are designed to handle moderate to heavy loads and are durable.

There are two main types of welded rod hydraulic cylinders. They include single-acting and double-acting models. Double-acting models are ideal for precision operations and high-pressure applications. They are manufactured with additional features for increased durability.

The standard hydraulic cylinder is composed of a cylinder barrel, a piston rod, and a seal. These three elements provide stability, control, and protection from leaks. The piston rod is made from medium carbon steel S45C, which is polished to mirror class.

To ensure that the hydraulic cylinder performs efficiently, it needs to have a smooth surface. This is achieved through honing. In addition, the inside of the cylinder tube must be durable. It is also important to maintain a clean working environment.

Welded rod hydraulic cylinders have more complex designs than tie rod cylinders. These cylinders use high-strength threaded steel rods to hold end caps together. Threaded bolts extend from bottom caps to top caps. This design makes it easy to disassemble and service the cylinder.

The most common applications for welded rod hydraulic cylinders are mobile equipment. These cylinders are used in construction, metal fabricating, OEM trailer manufacturing, and agricultural applications.

Tie rod hydraulic cylinders are also popular. They work well in low-pressure applications. They can be disassembled easily using standard tools. They are also less expensive to manufacture. However, they are less durable than welded cylinders.

Welded rod hydraulic cyclinders are durable, compact, and ideal for industrial and commercial applications. They are also lightweight, making them perfect for heavy-duty applications. They have a low profile design, which helps them to fit in tight spaces. They can also be custom-engineered to meet specific technical requirements.

The main advantages of welded rod hydraulic cylinders are their rugged design, durability, and versatility. They are suitable for a variety of mobile hydraulic equipment, and are ideal for applications that require precise parameters.

editor by czh 2023-07-03