Product Description

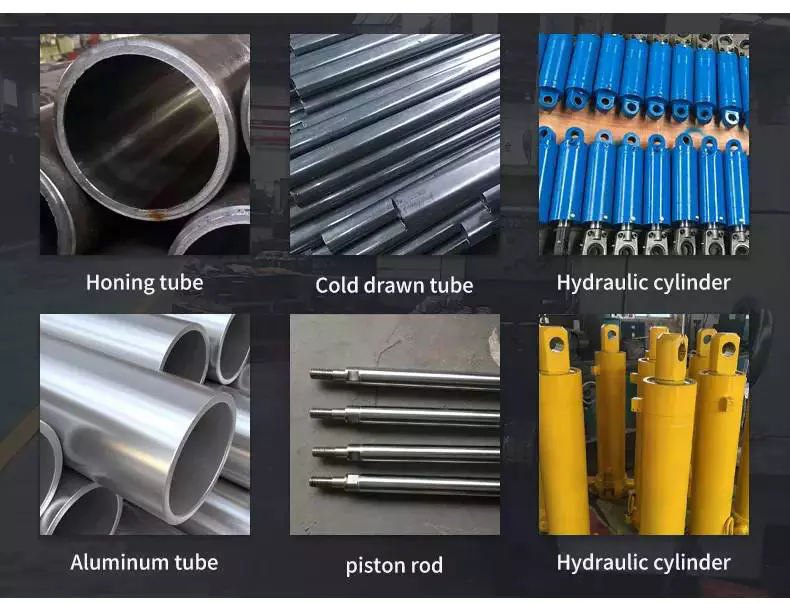

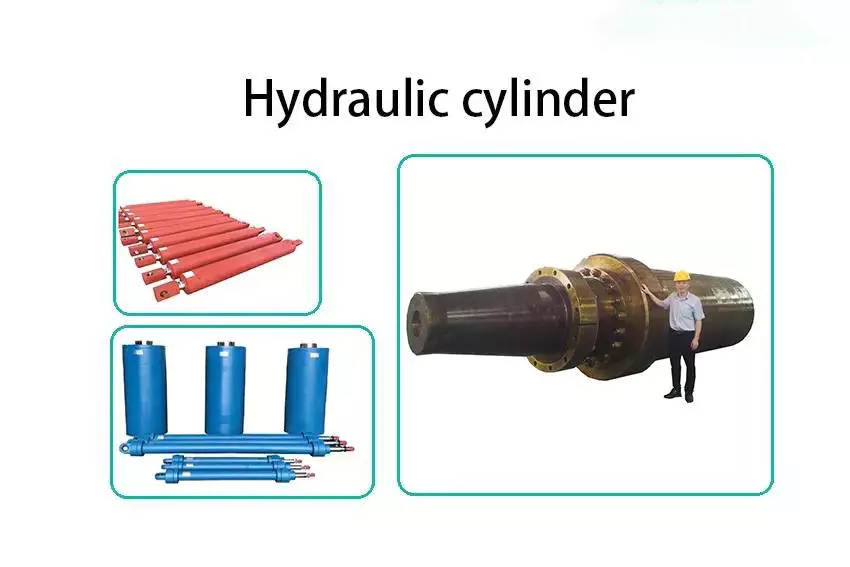

Hydraulic Cylinder Product Selling Points:

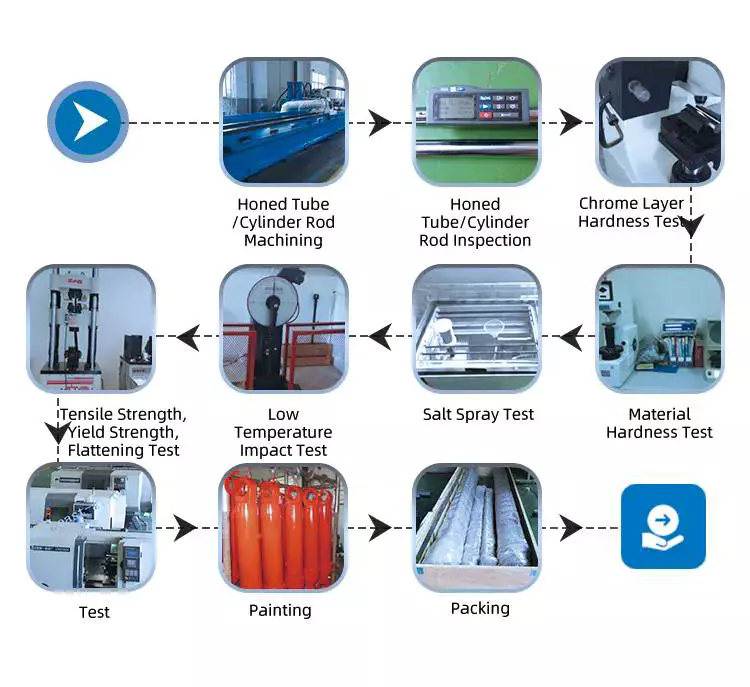

1. High Durability: The hydraulic cylinder is designed to withstand high pressure and heavy loads, ensuring long-lasting performance in even the most demanding applications.

2. Customizable Options: Our hydraulic cylinders can be customized to fit your specific needs and requirements, including bore sizes, stroke lengths, and mounting options.

3. Efficient Operation: The hydraulic cylinder provides efficient power transfer, allowing for smooth and precise movement of heavy equipment and machinery.

4. Low Maintenance: The hydraulic cylinder is designed for easy maintenance and repair, with minimal downtime required for servicing.

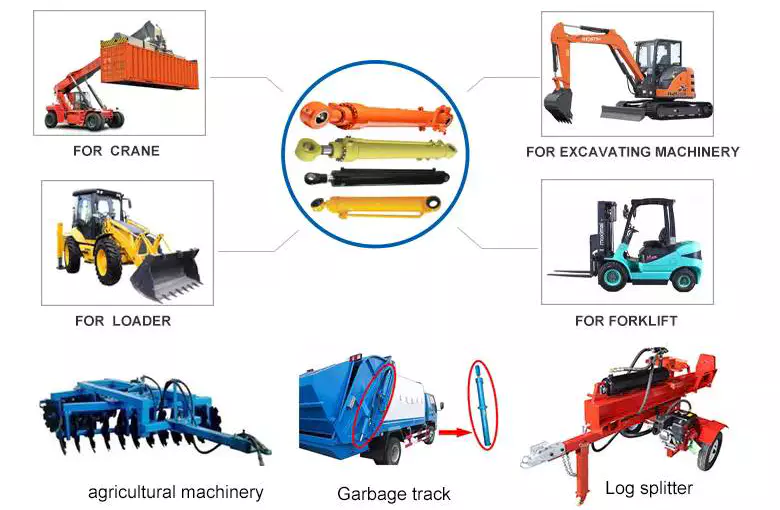

5. Wide Range of Applications: Our hydraulic cylinders can be used in a variety of industries, including construction, agriculture, mining, and transportation.

6. Quality Assurance: Our hydraulic cylinders are manufactured to strict quality standards, ensuring reliable and consistent performance.

7. Competitive Pricing: We offer competitive pricing on our hydraulic cylinders, making them a cost-effective solution for your equipment needs.

In summary, our hydraulic cylinders provide high durability, customizable options, efficient operation, low maintenance, a wide range of applications, quality assurance, and competitive pricing, making them an excellent choice for your equipment needs.

About Us

HangZhou LD Cylinder Co., Ltd. was founded in 1988, LD covers an area of 380,000sq.ft with more than 150 workers.

Through the construction of modern factories, enterprises have realized the transformation from traditional manufacturing to a new model of intelligent manufacturing.

LD application of highly intelligent system software, advanced process flow, automated production lines, innovative technology research and development design, It makes LD developed into a high-tech professional production of hydraulic cylinder Company.

FAQ

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | ISO9001 |

|---|---|

| Pressure: | Medium Pressure |

| Work Temperature: | Normal Temperature |

| Acting Way: | Single Acting |

| Working Method: | Straight Trip |

| Adjusted Form: | Regulated Type |

| Customization: |

Available

| Customized Request |

|---|

Choosing Seals and Mounting Options for Hydraulic Cylinders

Basically, a hydraulic cylinder is a mechanical actuator. It’s used in many different industries including construction, manufacturing, and civil engineering. These cylinders are designed to provide a single, unidirectional force.

Common seals

Choosing the right seals for hydraulic cylinders is crucial to the overall performance and durability of the system. Seals must be able to resist a wide range of temperatures, and also withstand pressure. Seals must also be compatible with the hydraulic fluid used in the system.

Seals can be made from a wide variety of materials. These materials include rubber, thermoplastics, metal, leather, and felt. These materials all serve different purposes. Some seals are designed to add strength to the cylinder, while others are designed to prevent leakage.

Rubbers are commonly used for dynamic seals in the fluid power industry. They are characterized by high tensile strength, high stiffness, and resistance to abrasion and weathering. They can handle a wide range of temperatures, and can withstand water, ozone, and oxygen. They are also resistant to tearing and abrasion.

Metal materials are used for rod and piston seals. They can be made from bronze, carbon steel, stainless steel, or aluminum. They can also be galvanized for added strength. Metals can be plated for oxidation protection. They may also be bonded with thermoset materials to provide enhanced sealing capabilities.

Thermoplastic elastomers provide excellent resistance to wear and pressure. They are also characterized by elasticity and flexibility. These materials have high tensile strength and low compression set. They are also resistant to abrasion, tearing, and abrasive wear. They can be bonded to rigid plastics to increase their durability and sealing performance.

Seals are used in hydraulic cylinders to protect the cylinder from contaminants and dirt. They also prevent leakage of the hydraulic fluid. Seals can be used in higher pressure systems, though they may not be suitable in low-pressure systems. Seals may also need to be compatible with additives used in hydraulic fluids.

Piston seals

Choosing the right piston seals for hydraulic cylinders is a key factor in obtaining the best performance for your application. Seals should be able to provide reliable sealing without leakage, and prevent contaminants from entering the cylinder. A wide range of materials are available for piston seals, including plastic, rubber, and fluorocarbon. Choosing a seal that meets your application’s mechanical, chemical, and temperature requirements is also important.

Polytetrafluoroethylene (PTFE) piston seals are highly recommended. They offer excellent resistance to wear and a high temperature range. This material is also compatible with many media. They are available in a wide range of seal designs, including single-acting and double-acting. They are also available with or without anti-extrusion rings.

A wide range of piston seals are available for hydraulic cylinders. Double-acting seals, for example, contain pressure on both sides of the piston without leakage. They are typically manufactured from Turcon(r) polytetrafluoroethylene, which is specially engineered for fluid power applications.

Single-acting piston seals are designed to contain pressure on one side of the piston. They can be symmetrical or asymmetrical. Asymmetrical seals include single-acting metric U-Cup designs, which can be manufactured from a wide range of materials, including fluorocarbon.

Double-acting piston seals provide the best sealing capacity of double-acting hydraulic cylinders. These seals are capable of sealing dynamic pressure on both sides of the piston, providing maximum sealing capacity for a wide range of cylinder applications. They are also designed to maintain low friction.

Choosing the right piston seals for hydraulic applications is important to reduce the risk of damage to a machine. Hydraulic cylinder seals are designed to retain hydraulic fluids and to exclude both solid and liquid contaminants. If a seal is leaking, or not exerting enough pressure, the pressure can drop, reducing the capacity of the cylinder to perform its work.

Rod seals

Choosing the right hydraulic rod seal is an essential part of maintaining the pressure in a hydraulic system. In addition, the seal must provide a thin layer of lubrication to the piston rod to prevent corrosion. Rod seals come in many different sizes and designs. They must also withstand the pressures generated in position-holding operations.

The most common materials used for hydraulic rod seals are PTFE-based materials. These materials are specifically engineered for fluid power applications and offer outstanding temperature performance.

These seals are designed to reduce friction losses, which can be 30 to 70 percent. This helps to minimize the impact on operating budgets and the environment.

In addition, rod seals can also be used as secondary seals in a sealing system. A secondary seal works in conjunction with a primary seal to reduce the load placed on the primary seal. This can also reduce the amount of pressure peaks in the system.

The primary seal and the secondary seal work together to ensure that the cylinder leaks to the exterior, and that the piston remains radially centered in the cylinder assembly. The primary seal is designed to withstand high operating pressures. It is usually made of Turcon(r) PTFE-based material.

When a rod seal leaks, it can be dangerous. It can cause problems with the hydraulic system, as well as environmental concerns. The best solution is to choose a seal that has a backup ring. This will ensure that the seal is able to withstand side-loading, while still allowing lubrication to pass through.

Rod seals for hydraulic cylinders can be made of a variety of materials. The choice of material must be made according to the pressure and temperature requirements of the hydraulic system. The material should also be chosen based on the type of fluid being used.

Welded connections

Whether you’re buying hydraulic cylinders for a new application or repairing a cylinder, you need solid welds to prevent joint failure. Incorrect welding can cause distortion and residual stresses that will ruin your system. A certified welder can create an effective weld between dissimilar metals.

In the field of hydraulic repair, four welding processes are the most common. They are friction welding, MIG (stick welding), friction welding, and friction welding with a laser beam.

Tie rod style hydraulic cylinders use high-strength threaded steel rods. They are usually off-the-shelf items. They are usually used in industrial factory applications. They are also prone to stretching over their service life.

Welded hydraulic cylinders are designed for rugged industrial environments and perform well in tough conditions. They have a more complex design, but are generally a better solution for most applications.

Cylinders made with welded connections have a higher service life than those made with tie rods. Welded cylinders have less distortion and heat than tie rod cylinders. They also have more options for customising their design.

For example, you can have welded hydraulic cylinders with special features, such as grease zerks, and special features added to the rod rod. In a heavy-duty application, you can add a piston seal to eliminate leaks. During repair, you may also want to add mounting attachments to the piston rod.

In a heavy-duty application, you’ll find that welded cylinders have a larger bore size. This allows for more pressure and force. You can also find heavy-duty cylinders that can withstand a 3,000 pound force per square inch pressure.

You’ll find that welded cylinders are more expensive than tie rod cylinders. They also require a different set of tools. These cylinders are also more difficult to repair.

Mounting options

Choosing the correct mounting options for hydraulic cylinders is important for minimizing accelerated wear and maintaining a cylinder’s best performance. A wide variety of mounts are available to suit a wide range of applications. Each system has its own advantages and disadvantages.

A flange mount is a fixed centre-line of the cylinder. It provides good strength, rigidity and stability. It is a good choice for stationary cylinders. Flange mounts are especially useful for applications that require straight-line force transfer. They are not as tolerant to misalignment as other cylinder mounts.

The clevis mount is one of the most common mounting options for hydraulic cylinders. It is attached to the cylinder cap, which is usually the end cap, or cylinder head. These mounts are usually used in mobile hydraulics. They offer good strength, rigidity and stability, but they are not as tolerant to misalignment as other cylinder mounts.

Pivot mounts are also available for hydraulic cylinders. They allow the cylinder to pivot in a single range of motion. They are available with a cap spherical bearing. They are best for short-stroke applications. Pivot mounts are also available with an intermediate fixed trunnion. They provide stability, strength, and a centerline mounting advantage.

Centerline cylinder mounts are a good choice for ensuring longevity. They provide support along the centerline, which helps absorb forces in a straight line. They are also best for applications with high internal pressure. They can be used in conjunction with tie-rod mounts to support the rods in compression.

Clevis bracket cylinder mounts provide support against side loading, which is important in a number of applications. These mounts can be installed into standard bore sizes, and have a double-tang design for improved rigidity and strength. They also have snap rings and cotter pins to hold the mounting bracket in place.

editor by Dream 2024-05-08

China Standard Replacement Hydraulic Parts Cat 320L Boom Arm Bucket Cylinder for Excavator hydraulic cylinders for sale

Product Description

Company introduction

HangZhou Roca is a comprehensive manufacturing enterprise engaged in hydraulic cylinders, excavator attachment, metal casting, hydraulic components with certification approval to meet custom or OEM requirements.

ROCA owned factory offers customers effective-cost products with quality assurance. With its professional and experienced R&D team, ROCA Hydraulic devotes itself to research and development to optimize products applied in construction, mining, waste management, forestry, agriculture, etc.

Model

CAT Series -320L

Stick Number : 0571 422

Boom Number : 1589058

Bucket Number : 7Y5100

Product introduce

CAT excavator 320L boom cylinder ,arm cylinder,bucket cylinder

Our excavator hydraulic cylinder has 3 types,boom cylinder,arm cylinder,also named stick cylinder,bucket cylinder, we also can make bulldozer hydraulic lift cylinder.

They are made from good material that are heat-treated and hardened to improve the lifespan while meeting the demanding requirements of earthmoving and mining applications.

Цилиндр стрелы экскаватора CAT 320L, цилиндр рукояти, цилиндр ковша

| Working temperature | -40°C ~ 80°C |

| Max. duration of extension | 0.5 hour |

| Color | RAL9005,Customize |

| Material | CK45,ST52,ST52-3,27SiMn,Customize |

| Seal kit | SKF, Trelleborg, Halite, Chesterton, NOK, Kayaba |

| Piston rod | Hard chromed |

| Packaging | Plywood case |

| Warranty | 12 months |

| Payment | T/T |

Specification

| Max. Working pressure | 250bar |

| Weight | 143kg |

| Working volume | 43L |

| Total volume | 47L |

| Max. Cyl. Load (start tipping) | 345kN |

| Extension | 1 | 2 | 3 |

| Diameter | 149mm | 129mm | 110mm |

| stroke | 1060mm | 1085mm | 1085mm |

Pictures

Excavator is the most widely used construction machinery.

The shock load, harsh working environment, precision movement control require high standards on excavator cylinders.

ROCA guarantees excavator cylinder high performance of abrasion resistance and operation stability in any harsh condition has and gains recognition from every solid customer with good quality at a lower cost.

Roca manufactures full-size excavator cylinders for mini excavators to largeexcavators.

Xihu (West Lake) Dis. Mining Group Co., Ltd. is a sizable multinational mining group performing most competitively in Chinese mining industry. ROCA locate in the same CZPT Mining output area, as the mining cylinder plant that grew up in the mining industry, we repair and reman a lot of mining haul truck cylinder. For a decade ROCA has been focused on the production of various types of imported mine-used off-highway trucks & mining trucks.Our cylinders are mainly applied to world-famous brands such as Cat, Komatsu, Hitachi, Liebherr, BELAZ, and other famous international brands.

Single-Acting Telescopic Cylinders

This type of cylinder applies hydraulic pressure in 1 direction only and the return of the telescopic stages is by load such as a truck-trailer.

ROCA single-acting multistage hoists are used widely throughout the transport sector, where they are used in tip trucks servicing agriculture, earthmoving, construction, food processing applications.

Double-Acting Telescopic Cylinder

This type of cylinder is constructed with porting to both the annular and full bore area so hydraulic pressure can be applied to both surfaces and the cylinder stages can move in multiple directions without the need of an outside force, such as gravity.ROCA double-acting multi-stage cylinders are used in a wide variety of applications across many industries where space restrictions prohibit the use of a rod cylinder and require a compact telescopic cylinder design.

There are a wide range of products in the cylinder industry and having a specialist working on behalf of the customer is very important. With our years of experience, our business is positioned to provide prompt service, value and long lasting customer relationships.We work toward getting you better products and better service with competitive price.

FAQ

Q1.Do you have MOQ?

Depending on different ideas, Can be negotiated. The larger the quantity is, the competitive the unit price will be.

Q2.Should the customer pay the delivery fee, How much is it?

For the delivery fee, many samples are being requested to be sent, so we must get the delivery fee.

If you tell me to use the appointed Express, you will give me your express account or you will pay according to the Express.

If you do not request, I will choose a cheap one in China.

Q3.How about the after sale service?

1) We will always keep the quality the same as the buyer’s samples and if there is something with the quality, we will make compensation for our customers.

2) We will suggest our packing and take charge in our packing, we will keep the goods safe in the delivery.

3) We will trace the goods from the production to selling, we will solve the problems in the selling for our customers.

Q4.When can I get a price?

We usually quote within 24 hours after we get your inquiry.

Q5: Are you a trade company or manufacturer?

We are a professional manufacturer with our factory.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | GS, RoHS, CE, ISO9001 |

|---|---|

| Pressure: | Medium Pressure |

| Work Temperature: | Low Temperature |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Buying Guide For Hydraulic Cylinders

Whether you are looking to replace a broken hydraulic cylinder or are interested in learning more about them, you will be glad to know that there are many options to choose from. The materials used to build cylinders, their stroke lengths and seals are just a few things to consider.

‘Parallel’ vs ‘Series’ cylinders

Choosing a hydraulic cylinder that is a good fit for your application is important. In general, there are two types of hydraulic cylinders: single-rod and tandem. In tandem cylinders, the two cylinders move in unison. This is the best way to transfer energy.

A welded body hydraulic cylinder is the most common type of hydraulic cylinder. It is used in construction equipment and other heavy industries. The cylinder body is welded in place and the base end is welded to it. It is normally rated for higher pressures.

A welded body hydraulic cylinder also has a built-in directional control valve. This valve works on both the inlet and the work ports. The oil from the pump goes through the control valves in series. This type of control valve usually has a small orifice drilled into it. It creates a pressure differential that forces the cylinders to work in unison.

Another type of hydraulic cylinder is the tie rod cylinder. It has a barrel and piston rod that is mounted on the bottom of the barrel. The piston rod operates both inside the barrel and out of the barrel.

There are many other types of hydraulic cylinders. Some of the more common include the plunger type, the tie rod type, and the single rod type. There are also many other types of cylinders, but they all have one thing in common: they use hydraulic fluid to power the piston.

The best hydraulic cylinder is one that can lift its weight. It is also important to select the best size for your application. The size of the cylinder depends on the load you intend to lift. If the loads are too large, you may have a difficult time maintaining synchronization. However, if the loads are not too heavy, you may be able to achieve the desired performance.

The hydraulic series relationship is a good place to start. If the loads are evenly distributed, the cylinders will work in unison. The flow control valves are a good way to keep cylinders in sync. A pilot-operated check valve is a good choice, as it will stop oil transfer when the mid-stroke is stopped.

Stroke lengths

Regardless of whether you’re buying a hydraulic cylinder for a small engine or a large excavator, the following guide can help you determine the optimal stroke length. The length is measured in inches. This is a standard measurement and is easy to obtain. The stroke is the distance covered by the rod and piston between the fully extended height and the fully retracted height of the cylinder.

The cylinder’s stroke can be measured in one of three ways. It can be based on the diameter of the rod, the diameter of the bore, or the difference between the maximum extended length and the minimum extended length. The cylinder’s stroke can range from a fraction of an inch to several feet. The stroke is a good indicator of the length of pull that can be exerted from the piston.

The largest part of the hydraulic cylinder is the rod. It is a round chrome-plated steel bar that performs the reciprocating motion. The diameter of the rod ranges from a few inches to twenty inches. It is referred to as the shiny part of the cylinder.

The retracted length is the distance between the centers of the mounting pins when the cylinder is closed. It is a standard measurement and can be measured with a tape measure. The retracted length is important for the proper functioning of the cylinder.

Using the retracted length, calculate the cylinder’s stroke. The stroke is the distance covered by the piston and rod between the fully extended height and the fully shortened height of the cylinder. This is the best indication of the length of pull that can be exerted.

The stroke is also the best indication of the length of lift that can be exerted from the piston. It can be measured using a caliper. The caliper can be used to measure the diameter of the rod and the thickness of the piston. It can also be used to calculate the difference between the maximum extended length and the maximum retracted length. This gives you the maximum length in the retracted position.

Materials used

Various materials are used in the manufacture of hydraulic cylinders. The materials have to be tough and durable enough to withstand the pressures of the hydraulic fluid. Besides, the materials must also be compatible with the hydraulic fluid. If the materials are not strong enough, the cylinder may not fully stroke.

Hydraulic cylinders are made of steel and other durable materials. They can be used in a variety of applications. They are used in manufacturing, construction, mining, and industrial technology. They can also be found in the aviation and aircraft industry. They have also been used in forestry.

Most hydraulic cylinders are made of 1018/1020 cold rolled steel. They are usually coated with Hard Chrome Plating to prevent corrosion. A variety of coatings are also available for cylinders.

In hydraulic systems, the fluid used is usually mineral oil or water glycol. Some cylinders also use fire resistant water glycol-based fluid. However, this type of fluid may still cause lubrication problems.

Another material used in hydraulic cylinders is stainless steel. These are generally inexpensive and easy to find. They are also environmentally friendly and work well with fuels and solvents. They are also durable in acidic environments.

Composite materials have also been used in the aerospace industry for years. They have also been used in high pressure vessels for CNG storage. They have a higher strength to weight ratio than steel. They have also been used in the automotive industry for many years.

The seal, piston, and steel ring work together to provide stability and control. They can also help ensure that the cylinder remains in place. These materials are also used for double-acting cylinders, which have ports on either side of the piston rod. The pressure on both sides of the piston rod helps control the movement of the cylinder.

Another type of cylinder is the tie rod style. This type of cylinder uses high-strength threaded steel tie rods to secure the cylinder. The tie rods stretch at high pressures, which allows the cylinder to function efficiently. The cylinders are commonly used in industrial factory applications.

Seals

Choosing the right seals for hydraulic cylinders is crucial to the functioning of a hydraulic system. These seals are designed to protect the internal components of the cylinder from contamination and leakage. They are used in various industries, including construction, agriculture and industrial plants.

Hydraulic cylinder seals come in a variety of designs. They are used in both static and dynamic applications. They are also subjected to high temperatures and high pressures. Therefore, they must be made of the right material to withstand the tough conditions. The seals must also be able to resist the change of hydraulic fluid.

Hydraulic cylinder seals are made from materials such as PTFE, polyurethane and rubber. These materials provide a durable seal for cylinders. They are also resistant to abrasion and tearing.

Seals for hydraulic cylinders are categorized into static and dynamic designs. Static seals are typically found in round cross-sections. They are used between the piston and the cylinder pipe. They are also known as gland seals. These seals are usually attached to the cylinder pipe with a threaded connection. The gland seal usually includes a wiper ring that keeps the interior of the cylinder clean and free from contamination.

Hydraulic cylinder seals also must be able to withstand high temperatures and high pressures. They are used in a variety of applications, including logging equipment. The main sealing material for hydraulic cylinders is polyurethane.

Seals for hydraulic cylinders can be made from thermoplastic or elastomeric polymers. These materials combine the strength of plastic with the flexibility of rubber. Thermoplastic elastomers also have better elasticity, enabling them to maintain constant pressure for longer periods of time.

In dynamic sealing systems, low friction coefficients are a basic requirement. This is due to the need for maximum tightness in dynamic conditions. Seal materials must also be capable of forming a tight seal against irregular metal surfaces.

The seal material must also be able to expand rapidly to follow dimensional changes. This is important for high-pressure cylinders, as they may undergo deformation. It is also important to use a material that can withstand corrosion.

editor by Dream 2024-05-02

China high quality Cat320c 360 330 235 E120 Excavator Hydraulic Cylinder Arm Boom Bucket Cylinder vacuum pump distributors

Product Description

| heavy duty hydraulic cylinders used for excavator | |||

| Part number | Tube dia mm | Rod dia mm | Stroke mm |

| 205-63-57100 | 120 | 85 | 1285 |

| 206-63-57100 | 120 | 85 | 1285 |

| 205-63-57160 | 120 | 85 | 1285 |

| 205-63-57120 | 135 | 95 | 1490 |

| 203-63-57130 | 125 | 85 | 1120 |

| 203-63-57131 | 125 | 85 | 1120 |

| 205-63-57130 | 125 | 85 | 1120 |

Specifications

1.Supply to USA,Europe,and Australia, Russia.

2.Material:Stainless Steel

3.Professional performance excavator parts supplier

4. High quality and low price

FAQ

Q1: Are you Manufacture or Trade Company?

A1: We are manufacture,we have 20 years experience for supply Metal material and products in domestic.

Q2: How can we guarantee quality?

A2: Always a pre-production sample before mass production;Always final Inspection before shipment;

Q3: What is your terms of payment ?

A3: 1.T/T: 30% deposit in advance, the balance 70% paid before shipment

2.30% down payment, the balance 70% paid against L/C at sight

3.CHINAMFG negotiation

Q4: Can you provide Certificates for aluminum materials ?

A4:Yes,we can supply MTC-Material Test Certificate.

Q5: Can you provide sample?

A5: Yes, we can provide you sample, but you need to pay for the sample and freight firstly. We will return the sample fee after

you make an order.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | GS, RoHS, CE, ISO9001 |

|---|---|

| Pressure: | Medium Pressure |

| Work Temperature: | Normal Temperature |

| Acting Way: | Double Acting |

| Working Method: | Piston Cylinder |

| Adjusted Form: | Switching Type |

| Customization: |

Available

|

|

|---|

How do hydraulic cylinders handle the challenges of precise positioning and control?

Hydraulic cylinders are designed to handle the challenges of precise positioning and control with a combination of engineering principles and advanced control systems. These challenges often arise in applications where accurate and controlled movements are required, such as in industrial automation, construction, and material handling. Here’s a detailed explanation of how hydraulic cylinders overcome these challenges:

1. Fluid Power Control:

– Hydraulic cylinders utilize fluid power control to achieve precise positioning and control. The hydraulic system consists of a hydraulic pump, control valves, and hydraulic fluid. By regulating the flow of hydraulic fluid into and out of the cylinder, operators can control the speed, direction, and force exerted by the cylinder. The fluid power control allows for smooth and accurate movements, enabling precise positioning of the hydraulic cylinder and the attached load.

2. Control Valves:

– Control valves play a crucial role in handling the challenges of precise positioning and control. These valves are responsible for directing the flow of hydraulic fluid within the system. They can be manually operated or electronically controlled. Control valves allow operators to adjust the flow rate of the hydraulic fluid, controlling the speed of the cylinder’s movement. By modulating the flow, operators can achieve fine control over the positioning of the hydraulic cylinder, enabling precise and accurate movements.

3. Proportional Control:

– Hydraulic cylinders can be equipped with proportional control systems, which offer enhanced precision in positioning and control. Proportional control systems utilize electronic feedback and control algorithms to precisely regulate the flow and pressure of the hydraulic fluid. These systems provide accurate and proportional control over the movement of the hydraulic cylinder, allowing for precise positioning at various points along its stroke length. Proportional control enhances the cylinder’s ability to handle complex tasks that require precise movements and control.

4. Position Feedback Sensors:

– To achieve precise positioning, hydraulic cylinders often incorporate position feedback sensors. These sensors provide real-time information about the position of the cylinder’s piston rod. Common types of position feedback sensors include potentiometers, linear variable differential transformers (LVDTs), and magnetostrictive sensors. By continuously monitoring the position, the feedback sensors enable closed-loop control, allowing for accurate positioning and control of the hydraulic cylinder. The feedback information is used to adjust the flow of hydraulic fluid to achieve the desired position accurately.

5. Servo Control Systems:

– Advanced hydraulic systems employ servo control systems to handle the challenges of precise positioning and control. Servo control systems combine electronic control, position feedback sensors, and proportional control valves to achieve high levels of accuracy and responsiveness. The servo control system continuously compares the desired position with the actual position of the hydraulic cylinder and adjusts the flow of hydraulic fluid to minimize any positional error. This closed-loop control mechanism enables the hydraulic cylinder to maintain precise positioning and control, even under varying loads or external disturbances.

6. Integrated Automation:

– Hydraulic cylinders can be integrated into automated systems to achieve precise positioning and control. In such setups, the hydraulic cylinders are controlled by programmable logic controllers (PLCs) or other automation controllers. These controllers receive input signals from various sensors and use pre-programmed logic to command the hydraulic cylinder’s movements. The integration of hydraulic cylinders into automated systems allows for precise and repeatable positioning and control, enabling complex sequences of movements to be executed with high accuracy.

7. Advanced Control Algorithms:

– Advancements in control algorithms have also contributed to the precise positioning and control of hydraulic cylinders. These algorithms, such as PID (Proportional-Integral-Derivative) control, adaptive control, and model-based control, enable sophisticated control strategies to be implemented. These algorithms consider factors such as load variations, system dynamics, and environmental conditions to optimize the control of hydraulic cylinders. By employing advanced control algorithms, hydraulic cylinders can compensate for disturbances and achieve precise positioning and control over a wide range of operating conditions.

In summary, hydraulic cylinders overcome the challenges of precise positioning and control through the use of fluid power control, control valves, proportional control, position feedback sensors, servo control systems, integrated automation, and advanced control algorithms. By combining these elements, hydraulic cylinders can achieve accurate and controlled movements, enabling precise positioning and control in various applications. These capabilities are essential for industries that require high precision and repeatability in their operations, such as industrial automation, robotics, and material handling.

Utilizing Hydraulic Cylinders in Conjunction with Alternative Energy Sources

Hydraulic cylinders can indeed be used in conjunction with alternative energy sources. The versatile nature of hydraulic systems allows them to be integrated with various alternative energy technologies to enhance efficiency, control, and power generation. Let’s explore some examples of how hydraulic cylinders can be utilized alongside alternative energy sources:

- Hydraulic Energy Storage: Hydraulic cylinders can be employed in energy storage systems that utilize alternative energy sources such as renewable sources (e.g., solar or wind) or waste energy recovery. These systems convert excess energy into hydraulic potential energy by pumping fluid into a high-pressure accumulator. When the energy is needed, the pressurized fluid is released, driving the hydraulic cylinder and generating mechanical power.

- Wave and Tidal Energy Conversion: Hydraulic cylinders can be utilized in wave and tidal energy conversion systems. These systems harness the power of ocean waves or tidal currents and convert it into usable energy. Hydraulic cylinders, along with associated pumps and valves, can be used to capture and control the energy from the waves or tides, driving the cylinders and generating mechanical power or producing electricity.

- Hydroelectric Power Generation: Hydraulic cylinders play a crucial role in traditional hydroelectric power generation. However, alternative approaches such as small-scale or micro-hydropower systems can also benefit from hydraulic cylinders. These systems utilize natural or man-made water flows to drive turbines connected to hydraulic cylinders, which then convert the hydraulic energy into mechanical power or electricity.

- Hydraulic Actuation in Wind Turbines: Hydraulic cylinders can be employed in wind turbines to enhance performance and control. For example, hydraulic pitch control systems use hydraulic cylinders to adjust the pitch angle of wind turbine blades, optimizing their aerodynamic performance based on wind conditions. This allows for efficient power generation and protection against excessive wind loads.

- Geothermal Energy Extraction: Geothermal energy extraction involves utilizing the natural heat from the Earth’s interior to generate power. Hydraulic cylinders can be utilized in geothermal systems to control and regulate fluid flow, allowing for efficient extraction and utilization of geothermal energy. They can also be used in geothermal heat pumps for heating and cooling applications.

In summary, hydraulic cylinders can be effectively utilized in conjunction with alternative energy sources to enhance energy storage, power generation, and control. Whether it’s through hydraulic energy storage systems, wave and tidal energy conversion, hydroelectric power generation, hydraulic actuation in wind turbines, or geothermal energy extraction, hydraulic cylinders offer versatile and efficient solutions for harnessing and utilizing alternative energy sources.

How do hydraulic cylinders handle variations in load and pressure during operation?

Hydraulic cylinders are designed to handle variations in load and pressure during operation, making them versatile and efficient in various applications. Hydraulic systems use the principle of transmitting force through incompressible fluid to generate linear motion. Here’s a detailed explanation of how hydraulic cylinders handle variations in load and pressure:

1. Load Handling:

– Hydraulic cylinders are capable of handling different loads by utilizing the principle of Pascal’s law. According to Pascal’s law, when pressure is applied to a fluid in a confined space, the pressure is transmitted equally in all directions. In a hydraulic cylinder, the force applied to the piston results in an equal force output at the rod end of the cylinder. The size of the piston and the pressure exerted determine the force generated by the cylinder. Therefore, hydraulic cylinders can handle a wide range of loads by adjusting the pressure applied to the fluid.

2. Pressure Compensation:

– Hydraulic systems incorporate pressure compensation mechanisms to handle variations in pressure during operation. Pressure compensating valves or regulators are often used to maintain a consistent pressure in the hydraulic system, regardless of load changes. These valves automatically adjust the flow rate or pressure to ensure stable and controlled operation of the hydraulic cylinder. By compensating for pressure variations, hydraulic cylinders can maintain a consistent force output and prevent damage or instability due to excessive pressure.

3. Control Valves:

– Control valves play a crucial role in managing variations in pressure and load during hydraulic cylinder operation. Directional control valves, such as spool valves or poppet valves, control the flow of hydraulic fluid into and out of the cylinder, enabling precise control of the cylinder’s extension and retraction. By adjusting the position of the control valve, the speed and force exerted by the hydraulic cylinder can be regulated to match the load and pressure requirements of the application. Control valves allow for efficient handling of variations in load and pressure by providing fine-tuned control over the hydraulic system.

4. Accumulators:

– Hydraulic accumulators are often used to handle fluctuations in pressure and load. Accumulators store hydraulic fluid under pressure, which can be released or absorbed as needed to compensate for sudden changes in load or pressure. When the load on the hydraulic cylinder decreases, the accumulator releases stored fluid to maintain pressure and prevent pressure spikes. Conversely, when the load on the cylinder increases, the accumulator absorbs excess fluid to maintain system stability. By utilizing accumulators, hydraulic cylinders can effectively handle variations in load and pressure, ensuring smooth and controlled operation.

5. Feedback and Control Systems:

– Advanced hydraulic systems may incorporate feedback and control systems to monitor and adjust the operation of hydraulic cylinders in real-time. Position sensors or pressure sensors provide feedback on the cylinder’s position, force, and pressure, allowing the control system to make continuous adjustments to optimize performance. These systems can automatically adapt to variations in load and pressure, ensuring precise control and efficient operation of the hydraulic cylinder.

6. Design Considerations:

– Proper design considerations, such as selecting the appropriate cylinder size, piston diameter, and rod diameter, are essential for handling variations in load and pressure. The design should account for the maximum anticipated load and pressure conditions to ensure the hydraulic cylinder operates within its specified range. Additionally, the selection of suitable seals, materials, and components that can withstand the anticipated load and pressure variations is crucial for maintaining the reliability and longevity of the hydraulic cylinder.

By utilizing the principles of hydraulic systems, incorporating pressure compensation mechanisms, employing control valves and accumulators, and implementing feedback and control systems, hydraulic cylinders can effectively handle variations in load and pressure during operation. These features and design considerations allow hydraulic cylinders to adapt and perform optimally in a wide range of applications and operating conditions.

editor by CX 2024-04-13

China Professional Excavator Hydraulic Arm Boom Bucket Cylinder PC30 PC55 Ex120-2 PC130 Ex200-1 Js200 PC200-8 Sk200-8 PC220 Dh500 Ec700 for Sale hydraulic cylinders end

Product Description

Product Description

A: Product Description

| Commodity Name | telescopic cylinder, telescopic hydraulic cylinder |

| Suitable Model | dump truck, dump tractor |

| Original | ZheJiang , China |

| Warranty | One year |

| Min of quantity | 1 piece |

| Packing | standard export wooden box or as your require |

| Time of Shipment | Usual 30-60days. Different according the quantity of order. |

| Port of Delivery | HangZhou, China |

Product Parameters

Product Overview

Factory Direct Sale 5 Stage Telescopic Hydraulic Cylinder.

We are the top machinery production and processing factory in China, with more than 10 years of export experience, and our after-sales service satisfaction ratio is always 100%. Due to our advantages in product quality, price and service, our sales are all from old customers’ return orders. We want to cooperate with medium and large buyers, our service will make you satisfied, to achieve a CZPT situation.

FEATURES AT A GLANCE

If you are a medium and large buyer, then we are definitely your best choice, our after-sales satisfaction is 100%, we have more than 10years of production and export experience, have a foreword and mature R & D ability.

Seals: Hallite, Parker, Merkel, etc.

Painting: anti rust painting

Certificate: ISO9001,SGS, CE, BV, TUV

Shaft diameter: 15mm to 600mm

Model number: double acting or single acting

Stage: Up to 5 level

Process: CNC Lathe Machining, CNC Cleaning Machining Robot welding, Milling

Testing Equipment: digital ultrasonic flow detector, ZEISS metallurgical microscope, ultrasonic thickness gauge, CAAM, Projector, Pin Gauge, etc

Application: Agricultural, Industrial, Engineer, Construction etc

Keyword: Double Acting Telescopic Hydraulic Cylinder,

After Warranty Service: Online support, Video technical support

Color: blue, red, yellow, green,grey, black, or Client’s Request

Size: Custom

MOQ: 1

Lead time: 30~40days

Customization: customized logo, customized package (min. Order 1 piece)

Shipping: sea freight, land freight, express, air freight

Protection: On-time dispatch is guaranteed

Supply Ability Supply Ability 3000 Pieces per Month

*We can customize and design according to your needs

*We can also produce according to your drawings

*If you need any hydraulic cylinder, please feel free to contact us

Successful Project

Our service/certifications

—CE Certificate of Quality Checked

—Adopt ISO Certificate of Quality Management System

—BV Certificate of Main Products Line verification

—Fast Delivery

—After-sales Service

—24 Hours, 7 Days on-line Service

KENDE is a leading global designer, manufacturer and marketer of hydraulic cylinder,cab, oil tank, counterweight, boom, arm, bucket, chassis, outrigger, pipe, hose, fitting, valve block, tyre, wheel,and other parts. Products are widely used in construction, mining, crane, material handing, automobile, truck, transportation, oil and gas, farm and garden equipment and so on .

We supply a wide range of parts for excavators, loaders, drills, dumpers, forklifts, tractors, trailers, harvestors, cars, buses, trucks and so on. Our products are focused on improved efficiency and life of the machineries and equipments.

Founded in January of 2015, we have become a big group till now which has 3 factories in asia to supply a wide range of products and service for the global customers.

We have the most advanced production equipments and specialized R &D center to assure the highest quality products to customers.

Our vision statement is “Science and technology first, Always with a grateful heart, Walk the world by virtue, Struggle for a better future”

Certifications

FAQ

FAQ

1)>. How about your delivery time?

: Generally, it will take 30 to 60 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

2)>. What is your terms of price?

: EXW, FOB, CFR, CIF, DDU.

3)> . What is your terms of payment?

: T/T 50% as deposit, and 50% before delivery. We’ll show you the photos of the products and packages before you pay the balance.

4)> . Can you supply a sample freely?

: Sorry, we only can produce the sample with the cost price for you.

5)> Can you produce according to the samples?

: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

6)>. What is your sample policy?

: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

7)>. Do you test all your goods before delivery?

: Yes, we have 100% test before delivery

8)>: How do you make our business long-term and good relationship?

:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Pressure: | High Pressure Low Pressure Medium Pressure, High Pressure Low Pressure Medium Pressure |

|---|---|

| Work Temperature: | High Temperature Low Temperature Normal Temperat, High Temperature Low Temperature Normal Temperat |

| Acting Way: | Double Acting Single Acting, Double Acting Single Acting |

| Working Method: | Straight Trip, Straight Trip |

| Adjusted Form: | Regulated Type, Regulated Type |

| Structure: | Piston Type, Piston Type |

| Customization: |

Available

| Customized Request |

|---|

Choosing Hydraulic Cylinders

Typically, hydraulic cylinders are used in applications such as manufacturing machinery, construction equipment, and civil engineering. They are also used in elevators and other applications where the use of a mechanical actuator is necessary.

Piston seals

Choosing the correct piston seals for hydraulic cylinders can help to ensure the proper operation of the cylinder. Seals are designed to keep fluids and contaminants from flowing across the cylinder. However, external factors can affect their performance. In order to choose the right seals, it’s important to understand the different types.

There are two basic piston seal types. One is a double acting seal that maintains pressure on both sides of the piston. The other type is a single acting seal that maintains pressure on only one side of the piston.

Double acting piston seals are typically made of a slide ring. They maintain the pressure in a hydraulic cylinder and allow the ram to move in a controlled direction. The slide ring is normally made of a plastic material. However, it is important to select a material that is suitable for the fluid pressure that is expected.

Single acting cylinder seals are designed for cylinders where one side of the piston is under high pressure and the other side is under low pressure. These seals are usually designed to provide the best sealing characteristics.

In addition to the seal, it is important to select the right guide. A guide is a metal strip or ring that keeps the piston and the piston rod radially centered in the cylinder assembly. This guide also keeps metal-to-metal contact between the two components.

For high-pressure applications, it is recommended to use piston seals made from PTFE. These seals can withstand temperatures up to 800 degrees Celsius. They have less friction than rubber seals and are also resistant to abrasion. However, they are not as durable as thermoplastic elastomers.

The seals are designed to maintain a constant pressure for a longer period of time than other materials. In addition, they are resistant to tearing, and they stand up to high use.

Coatings for hydraulic cylinders

Various coatings for hydraulic cylinders are available in the market. The main purpose of these coatings is to provide protection against physical and chemical attacks. These coatings are usually applied externally or internally.

Plasma spray is one of the most common surface modification methods. It combines flame and arc spray to deposit metallic or ceramic materials onto the surface. This process improves the operating characteristics of actuators. It is also useful in repairing damaged surfaces.

Another popular surface treatment is liquid nitrating. It produces a hard iron nitride layer that has excellent surface hardness. It also provides a good surface resistance. It can be used as a thermal barrier coating on stationary gas turbine blades.

Hard chrome over nickel coating is also a common type of coating for hydraulic cylinders. It provides good corrosion resistance and abrasion resistance. It is plated onto the surface and then polished.

Another popular surface modification method is thermal spray. It uses engineered materials to deposit metallic or ceramic materials onto the surface. It is a cost effective solution to surface enhancement. It also eliminates the need for costly replacement parts.

In addition, WC-CoCr coatings provide good wear resistance and corrosion resistance. These coatings are particularly useful for parts that are subjected to harsh working conditions.

Ceramic plating is mostly used in the aerospace and military industries. It also reduces friction and provides heat shielding. It can also be used as an alternative to hard chrome coatings.

The most important mechanical properties are the hardness, yield strength and the tensile strength. The material selection should be based on the shape and dimensions of the object being produced. This article will discuss the most commonly used materials and give an overview of the most effective surface modification methods.

Double-acting cylinders

Basically, hydraulic cylinders are used in a variety of applications, including engineering, industrial furnaces, and lift shafts. They are also used in subsea environments, shipbuilding, and oil & gas.

A double-acting hydraulic cylinder is a type of hydraulic cylinder that combines the best features of a single-acting cylinder with some additional advantages. These benefits include higher force, greater flexibility, and more control. Double-acting hydraulic cylinders are generally used in high-powered applications, such as lift shafts, excavation equipment, and robotics. They are also used in mobile applications, such as earthmoving equipment.

The main difference between single acting and double-acting hydraulic cylinders is the way the piston is moved up and down the cylinder bore. Double-acting cylinders use hydraulic fluid to apply pressure on both sides of the piston rod.

Another advantage of double-acting hydraulic cylinders is their ability to extend and retract without the need for an external force. In contrast, single acting cylinders require an external source to move the piston.

Double-acting hydraulic cylinders are more expensive than single-acting cylinders. This is because they have a larger housing and require more dedicated maintenance. They are also more costly to buy.

However, they are also more accurate and efficient. Double-acting cylinders work faster and can be used in virtually any application. They are also better for industrial tasks, such as lifting merchandise off conveyor belts. They can also work in an angle, and they are suitable for mobile applications.

In addition to their performance, double-acting hydraulic cylinders are more likely to be ISO compliant than single-acting cylinders. They also offer more design options.

Depending on the needs of the application, a double-acting hydraulic cylinder may be more expensive than a single-acting cylinder. This is because the piston seal must be designed to work with the fluid. The seal material is generally rubber or a rubber/fabric composite.

Stainless steel cylinders

Stainless steel hydraulic cylinders are used in numerous industries. They are known for their durability and rust resistance. They are used in industrial hydraulics applications, as well as in the food and beverage processing industry. They also help processing facilities meet industry standards.

Stainless steel hydraulic cylinders are made of a stainless steel alloy that contains at least 10% chromium. The chromium oxide forms a thin layer on the steel’s surface, contributing to its corrosion resistance. The alloy also develops a non-porous surface that prevents bacteria from lingering. It also contributes to the steel’s ability to self-repair.

Stainless steel hydraulic cylinders are widely used in the food and beverage processing industry. They are particularly useful for moving heavy loads. They can withstand frequent cleaning operations. They also provide excellent strength. They are commonly used in chocolate molding machines and cold press juicers.

Stainless steel hydraulic cylinders are available from Maverick Machine & Hydraulics. They can be customized to meet your specifications. They can be manufactured with a satin finish or a streamlined design. They can also be custom colored. The manufacturer will provide full service and a competitive price.

Hydraulic cylinders are used to push, pull, or push-pull heavy loads. They are designed to withstand extreme temperatures. They are also available in single and double-acting configurations. They are commonly used in pharmaceutical, food, chemical, and marine applications. They are also used on coastal power generation plants and pipeline risers. They are also used in water treatment plants. They can also be used on oil platforms.

There are two types of hydraulic cylinders, which are single-acting and double-acting. The single-acting type has a single fluid chamber, while the double-acting model has more fluid in the pressurized chamber. The single-acting cylinder is more affordable to maintain and easier to control.

Pivot rod style cylinders

Choosing hydraulic cylinders requires a great deal of attention to detail. You will need to consider the following factors: cylinder length, rod size, rod seals, bearing loads, and the type of cylinder you need.

Hydraulic cylinders are used in a variety of applications, such as lifting and lowering buckets, as well as jack knifing and metal sheet shearing machines. They are also used in hydraulic bending machines and earth-moving equipment.

The main sleeve or barrel of a hydraulic cylinder extends to its maximum stroke. It can be either single or double acting, and can be either stationary or pivoting. This allows a cylinder to move a load in a straight line or a circular path.

Cylinders have a variety of mounting styles, including clevises, flanges, and side mounts. Flange mounts are generally used in force-transfer applications where the cylinder must be parallel with the load. Flanges come in several shapes and sizes, including a square flange, a rectangular head, or a cap. Aside from transferring load, they also absorb force along the cylinder centerline.

Cylinders have a variety and range of seals, which are used to prevent hydraulic fluid leakage past the interface. These seals are made of various materials, including metal and elastomeric seals. The materials used for these seals depend on the application. These seals also vary in terms of pressure, temperature, and temperature changes.

Clevises and flanges are two common mounting styles for hydraulic cylinders. They are used to provide structural support for bolts. These mounts also work to absorb force along the cylinder’s centerline. These mounting styles have less rod bearing loads than other types, but they must be properly aligned with the load.

editor by CX 2024-04-09

China Standard Arm Bucket Boom Hydraulic Cylinder for Excavator Dx210W Dx340 vacuum pump oil near me

Product Description

| heavy duty hydraulic cylinders used for excavator | |||

| Part number | Tube dia mm | Rod dia mm | Stroke mm |

| 205-63-57100 | 120 | 85 | 1285 |

| 206-63-57100 | 120 | 85 | 1285 |

| 205-63-57160 | 120 | 85 | 1285 |

| 205-63-57120 | 135 | 95 | 1490 |

| 203-63-57130 | 125 | 85 | 1120 |

| 203-63-57131 | 125 | 85 | 1120 |

| 205-63-57130 | 125 | 85 | 1120 |

Specifications

1.Supply to USA,Europe,and Australia, Russia.

2.Material:Stainless Steel

3.Professional performance excavator parts supplier

4. High quality and low price

FAQ

Q1: Are you Manufacture or Trade Company?

A1: We are manufacture,we have 20 years experience for supply Metal material and products in domestic.

Q2: How can we guarantee quality?

A2: Always a pre-production sample before mass production;Always final Inspection before shipment;

Q3: What is your terms of payment ?

A3: 1.T/T: 30% deposit in advance, the balance 70% paid before shipment

2.30% down payment, the balance 70% paid against L/C at sight

3.CHINAMFG negotiation

Q4: Can you provide Certificates for aluminum materials ?

A4:Yes,we can supply MTC-Material Test Certificate.

Q5: Can you provide sample?

A5: Yes, we can provide you sample, but you need to pay for the sample and freight firstly. We will return the sample fee after

you make an order.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | GS, RoHS, CE, ISO9001 |

|---|---|

| Pressure: | Medium Pressure |

| Work Temperature: | Normal Temperature |

| Acting Way: | Double Acting |

| Working Method: | Piston Cylinder |

| Adjusted Form: | Switching Type |

| Customization: |

Available

|

|

|---|

What advancements in hydraulic cylinder technology have improved sealing and reliability?

Advancements in hydraulic cylinder technology have continuously contributed to improving sealing and reliability in hydraulic systems. These advancements aim to address common challenges such as leakage, wear, and failure of seals, ensuring optimal performance and longevity. Here are several key advancements that have significantly improved sealing and reliability in hydraulic cylinders:

1. High-Performance Sealing Materials:

– The development of advanced sealing materials has greatly improved the sealing capabilities of hydraulic cylinders. Traditional sealing materials like rubber have been replaced or enhanced with high-performance materials such as polyurethane, PTFE (polytetrafluoroethylene), and various composite materials. These materials offer superior resistance to wear, temperature, and chemical degradation, resulting in improved sealing performance and extended seal life.

2. Enhanced Seal Designs:

– Advancements in seal designs have focused on improving sealing efficiency and reliability. Innovative seal profiles, such as lip seals, wipers, and scrapers, have been developed to optimize fluid retention and prevent contamination. These designs provide better sealing performance, minimizing the risk of fluid leakage and maintaining system integrity. Additionally, improved seal geometries and manufacturing techniques ensure tighter tolerances, reducing the potential for seal failure due to misalignment or extrusion.

3. Integrated Seal and Bearing Systems:

– Hydraulic cylinders now incorporate integrated seal and bearing systems, where the sealing elements also serve as bearing surfaces. This design approach reduces the number of components and potential failure points, improving overall reliability. By integrating seals and bearings, the risk of seal damage or displacement due to excessive loads or misalignment is minimized, resulting in enhanced sealing performance and increased reliability.

4. Advanced Coatings and Surface Treatments:

– The application of advanced coatings and surface treatments to hydraulic cylinder components has significantly improved sealing and reliability. Coatings such as chrome plating or ceramic coatings enhance surface hardness, wear resistance, and corrosion resistance. These surface treatments provide a smoother and more durable surface for seals to operate against, reducing friction and improving sealing performance. Moreover, specialized coatings can also provide self-lubricating properties, reducing the need for additional lubrication and enhancing reliability.

5. Sealing System Monitoring and Diagnostic Technologies:

– The integration of monitoring and diagnostic technologies in hydraulic systems has revolutionized seal performance and reliability. Sensors and monitoring systems can detect and alert operators to potential seal failures or leaks before they escalate. Real-time monitoring of pressure, temperature, and seal performance parameters allows for proactive maintenance and early intervention, preventing costly downtime and ensuring optimal sealing and reliability.

6. Computational Modeling and Simulation:

– Computational modeling and simulation techniques have played a significant role in advancing hydraulic cylinder sealing and reliability. These tools enable engineers to analyze and optimize seal designs, fluid flow dynamics, and contact stresses. By simulating various operating conditions, potential issues such as seal extrusion, wear, or leakage can be identified and mitigated early in the design phase, resulting in improved sealing performance and enhanced reliability.

7. Systematic Maintenance Practices:

– Advances in hydraulic cylinder technology have also emphasized the importance of systematic maintenance practices to ensure sealing and overall system reliability. Regular inspection, lubrication, and replacement of seals, as well as routine system flushing and filtration, help prevent premature seal failure and optimize sealing performance. Implementing preventive maintenance schedules and adhering to recommended service intervals contribute to extended seal life and enhanced reliability.

In summary, advancements in hydraulic cylinder technology have led to significant improvements in sealing and reliability. High-performance sealing materials, enhanced seal designs, integrated seal and bearing systems, advanced coatings and surface treatments, sealing system monitoring and diagnostics, computational modeling and simulation, and systematic maintenance practices have all played key roles in achieving optimal sealing performance and increased reliability. These advancements have resulted in more efficient and dependable hydraulic systems, minimizing leakage, wear, and failure of seals, and ultimately improving the overall performance and longevity of hydraulic cylinders in diverse applications.

How do hydraulic cylinders contribute to the efficiency of agricultural tasks like plowing?

Hydraulic cylinders play a crucial role in improving the efficiency of agricultural tasks, including plowing. These cylinders provide several benefits that enhance the performance and productivity of agricultural machinery. Let’s explore how hydraulic cylinders contribute to the efficiency of plowing and other agricultural tasks:

- Powerful Force Generation: Hydraulic cylinders are capable of generating high forces, which is essential for tasks like plowing. The hydraulic system supplies pressurized fluid to the cylinders, converting hydraulic energy into mechanical force. This force is then utilized to drive plow blades through the soil, overcoming resistance and facilitating efficient soil penetration. The power generated by hydraulic cylinders ensures effective plowing, even in tough or compacted soil conditions.

- Adjustable Working Depth: Hydraulic cylinders allow for easy and precise adjustment of the plow’s working depth. By controlling the extension or retraction of the hydraulic cylinder, farmers can adjust the depth of the plow blades according to soil conditions, crop requirements, or their specific preferences. This adjustability enhances efficiency by ensuring optimal soil tillage and minimizing unnecessary energy expenditure. Farmers can adapt the plowing depth to different field areas, optimizing the use of resources and promoting uniform crop growth.

- Responsive Control: Hydraulic systems offer highly responsive control, enabling farmers to make quick adjustments during plowing operations. Hydraulic cylinders respond rapidly to changes in hydraulic pressure and valve settings, allowing for immediate modifications in the plow’s position, depth, or angle. This responsiveness enhances efficiency by facilitating on-the-go adjustments based on soil variations, obstacles, or changing field conditions. Farmers can maintain precise control over the plow’s performance, ensuring effective soil tillage and minimizing the risk of crop damage.

- Implement Versatility: Hydraulic cylinders enable the attachment of various implements to agricultural machinery, expanding their functionality and versatility. In the context of plowing, hydraulic cylinders allow for the attachment and detachment of plow blades or other tillage implements. This versatility enables farmers to adapt their equipment to different soil types, field sizes, or specific plowing requirements. By using hydraulic cylinders, farmers can easily switch between different implements, optimizing their equipment for specific tasks and maximizing efficiency.

- Efficient Time Management: Hydraulic cylinders contribute to time efficiency in agricultural tasks like plowing. With hydraulic systems, farmers can operate plows at higher speeds while maintaining control and precision. The responsive nature of hydraulic cylinders allows for efficient turning, maneuvering, and repositioning of plows, minimizing downtime and optimizing field coverage. This time efficiency translates into increased productivity and reduced overall operational costs. Farmers can accomplish plowing tasks more quickly, allowing them to cover larger field areas in less time.

In summary, hydraulic cylinders significantly contribute to the efficiency of agricultural tasks like plowing. Through powerful force generation, adjustable working depth, responsive control, implement versatility, and efficient time management, hydraulic systems equipped with cylinders enhance the performance and productivity of agricultural machinery. These contributions allow farmers to accomplish plowing tasks more effectively, optimize field operations, and achieve improved overall efficiency in their agricultural practices.

What benefits do hydraulic cylinders offer for tasks requiring heavy lifting or movement?

Hydraulic cylinders offer numerous benefits for tasks that involve heavy lifting or movement. Their unique design and characteristics make them well-suited for applications that require substantial force, precise control, and reliable operation. Here are the detailed benefits that hydraulic cylinders provide for such tasks:

1. High Force Generation:

– Hydraulic cylinders are capable of generating significant amounts of force. By utilizing hydraulic pressure, which can be easily amplified, hydraulic cylinders can exert substantial force to lift and move heavy loads. The force output of a hydraulic cylinder is directly proportional to the hydraulic pressure and the surface area of the piston. This high force capability makes hydraulic cylinders ideal for tasks that involve heavy lifting, pushing, or pulling.

2. Precise Control:

– Hydraulic cylinders offer precise control over the force and motion they generate. By regulating the flow of hydraulic fluid into the cylinder, the speed, direction, and position of the cylinder’s movement can be accurately controlled. This level of control is crucial for tasks that require precise positioning, delicate movements, or synchronization of multiple cylinders. It enables operators to perform operations with accuracy and minimize the risk of damage or accidents.

3. Safety:

– Hydraulic cylinders are designed with safety features to ensure the protection of both personnel and equipment. They incorporate overload protection mechanisms, such as relief valves, that prevent excessive force or pressure from damaging the system. Additionally, hydraulic cylinders allow for controlled and gradual movements, reducing the risk of sudden and uncontrolled motions that could pose safety hazards during heavy lifting or movement tasks.

4. Versatility and Adaptability:

– Hydraulic cylinders are versatile components that can be adapted to meet specific requirements. They can be customized based on factors such as force capacity, stroke length, speed, and mounting options, allowing them to be integrated into various types of machinery. This versatility makes hydraulic cylinders suitable for a wide range of applications, including construction, material handling, mining, agriculture, and more.

5. Smooth and Controlled Operation:

– Hydraulic cylinders provide smooth and controlled operation, ensuring efficient and reliable performance during heavy lifting or movement tasks. The hydraulic fluid acts as a cushioning medium, which helps dampen shocks and vibrations, resulting in smoother and quieter operation. This controlled operation also reduces the risk of damage to the load being lifted or the surrounding equipment.

6. Compact Design:

– Hydraulic cylinders offer a high power-to-size ratio, allowing for compact machinery design. Their relatively small size, compared to the forces they can generate, makes them suitable for applications where space is limited or weight restrictions apply. This compact design enables the integration of hydraulic cylinders into different types of equipment without compromising performance or efficiency.

7. Durability and Reliability:

– Hydraulic cylinders are built to withstand rigorous operating conditions and provide long-term reliability. They are constructed with robust materials, precise machining, and effective sealing systems to ensure durability and prevent fluid leakage. Hydraulic cylinders can withstand high pressures, heavy loads, and continuous use, making them suitable for demanding tasks involving heavy lifting or movement.

8. Energy Efficiency:

– Hydraulic cylinders contribute to energy efficiency in tasks requiring heavy lifting or movement. Hydraulic systems allow for the transfer of power over long distances without significant power losses. Additionally, hydraulic cylinders can incorporate energy-saving features such as load-sensing technology and regenerative circuits, which reduce energy consumption by optimizing the use of hydraulic fluid.

In summary, hydraulic cylinders offer several benefits for tasks that involve heavy lifting or movement. They provide high force generation, precise control, safety features, versatility, smooth operation, compact design, durability, and energy efficiency. These advantages make hydraulic cylinders indispensable components in various industries where heavy loads need to be lifted, pushed, or moved with accuracy and reliability.

editor by CX 2024-04-08

China high quality CZPT CZPT Excavator Spare Parts Hydraulic Boom Arm Bucket Cylinder manufacturer

Product Description

ISO9001 standard Arm/bucket/boom excavator hydraulic cylinder for sale

Construction Equipment Hydraulic Cylinders

| Hydraulic cylinders that are used on construction equipment must be rugged and reliable.; They will experience a lifetime exposed to heavy use in a harsh environment.; Failure in service will result in costly downtime,; project delays and maintenance headaches.;

These cylinders must be designed to withstand the following:; |

1.;Rod seal:;superior quality named-brand seals improve a longer life and seal effect polyurethane U-packing rod seals/buffer seals · bonded-to-metal wiper seals custom seals available

2.;:;Skived&burnished or vertical honing tube assures the concentricity and straightness

3.;Bushing:;Hardened steel bushing or copper bushing

4.;Eye:;All eyes are made of forged high strenght steel improve cylinder not only in appearance but in mechanical performance

5.;Rod:;Induction hardened prior to chrome plating enhances the surface hardness,;enhanced chrome plating improve corrosion resistence and anti-scratch performance

6.;Piston:;High pressure piston sealing material:;teflon or nylon seals.;High precision machining maximize the consistency of parts.;

7.;Cap:;All caps are made of forged high strength steel

Technology

*Skive Roller Burnishing Machines

*Vertical Honing machine

*Mchining Centers

*CNC Lathes

*Automatic Welding Machines

*Grinders

*Polishing machine

*Cylinder Assembly Benches

*Cylinder Test Benches

*Spray room

Process flow

Materials feeling → Tempering → Cylindrical lathe cutting → High-frequency quenching → Cylindrical grinding → Hard chrome plating → External grinding

After tempering and surface high-frequency quenching,;external surface hard chrome

piating,; make it hard both internal and external with smooth surface.;

Piston rod:; Adopt high precision mirror polishing

| Material | 45# high grade carbon steel or 40CR |

| Tempering hardness | HB240-260 |

| The depth of the high frequency | 2mm-3mm |

| High frequency hardness | HRC55°±2° |

| Chrome plating thickness | 0.;03mm-0.;06mm |

| Chromium layer hardness | HV800-1000vpn |

| Straightness | ≤0.;08mm/m |

| Surface roughness | Ra0.;03um- Ra0.;06um |

| Outside diameter tolerance | f7 |

Hydraulic Cylinder Tube:; Using imported equipment rolling machine

| Kind of steel | 45# | Tensile strength N/mm | ≥647 |

| Linearity | 0.;3-1/1000 | Specific elongation | ≥4 |

| Precision of size | HB | 207 | |

| Roughness of inner hole | 0.;4-0.;8 |

HangZhou Fortune Machinery Co.;,; Ltd.; is 1 of main manufacturers and exporters of undercarriage parts for excavators and bulldozers for more than 15 years in China.; Its factory is located at HangZhou City of ZheJiang Province,; very near HangZhou Port with a very convenient transportation.;

HangZhou Fortune Machinery mainly supply undercarriage replacement parts such as track rollers,; top rollers,; sprockets,; segments,; idler assy,; track link assy,; track shoe,; bucket,; bucket teeth,; bucket link,; I link,; cutting side,; end bits,; long boom&arm,; bushings pins,; bolts and nuts for excavators and bulldozers.; Its products are applicable for most famous makes such as Komatsu,; Hitachi,; Caterpillar,; Kobelco,; Kato,; Daewoo,; Hyundai,; CHINAMFG and so on.; Most products are exported to European,; Southeast Asia,; Middle East,; South America etc.;

With the principal “Good quality and Best services at reasonable prices”,; we strive to continually improve our production technique to provide better products at better prices.; We cordially welcome the customers from all over the world to consult and visit,; on the basis of mutual benefit and creat refulgence together.;

|

BRAND |

|

|||||||

| KOMATSU | PC30 | PC40 | PC45 | PC60 | PC75 | PC100 | PC120 | PC200 |

| EXCAVATOR | PC220 | PC300 | PC350 | PC400 | ||||

| CATERPILLAR | E70B | E110 | E120 | E200B | E307 | E311 | E312 | E320 |

| EXCAVATOR | E322 | E325 | E300B | E330 | ||||

| KOMATSU | D20 | D21 | D30 | D31 | D37 | D40 | D50 | D60 |

| BULLDOZER | D63 | D65 | D80 | D85 | D135 | D155 | D355 | D375 |

| CATERPILLAR | D3C | D3D | D4 | D4C | D4D | D4E | D5 | D5H |

| BULLDOZER | D6 | D6C | D6D | D6H | D7E | D7G | D8N | D9N |

| HITACHI | EX30 | EX40 | EX60 | EX100 | EX120 | EX200 | EX220 | EX300 |